Prefabricated chimney caps are essential components for modern, factory-built fireplace systems. They prevent water damage, block wildlife, and extend your chimney’s life. If you have a newer home, you likely have a prefabricated chimney, which uses a metal flue pipe inside a wooden structure called a chase. This system requires a two-part defense: a large chase cover for the structure and a smaller flue cap for the pipe opening.

Without proper capping, your chimney is vulnerable to rain, animals, and debris. Water can rot the wooden chase, leading to expensive repairs. Animals can nest inside, creating fire hazards, while escaping sparks can ignite roofing materials.

Choosing the right prefabricated chimney caps involves understanding materials, styles, and accurate measurements. A poorly chosen or installed cap can fail quickly, leaving your home exposed. This guide covers everything you need to know to select, measure, and maintain your chimney caps, helping you avoid common mistakes that lead to water damage and costly Roof Repair Services.

Many homes built in recent decades, particularly from the 1980s onward, feature prefabricated chimneys instead of traditional, solid-masonry structures. This shift occurred largely due to the lower cost and faster installation time of factory-built systems. Understanding this modern system is the first and most critical step in choosing the right prefabricated chimney caps and ensuring your home is properly protected.

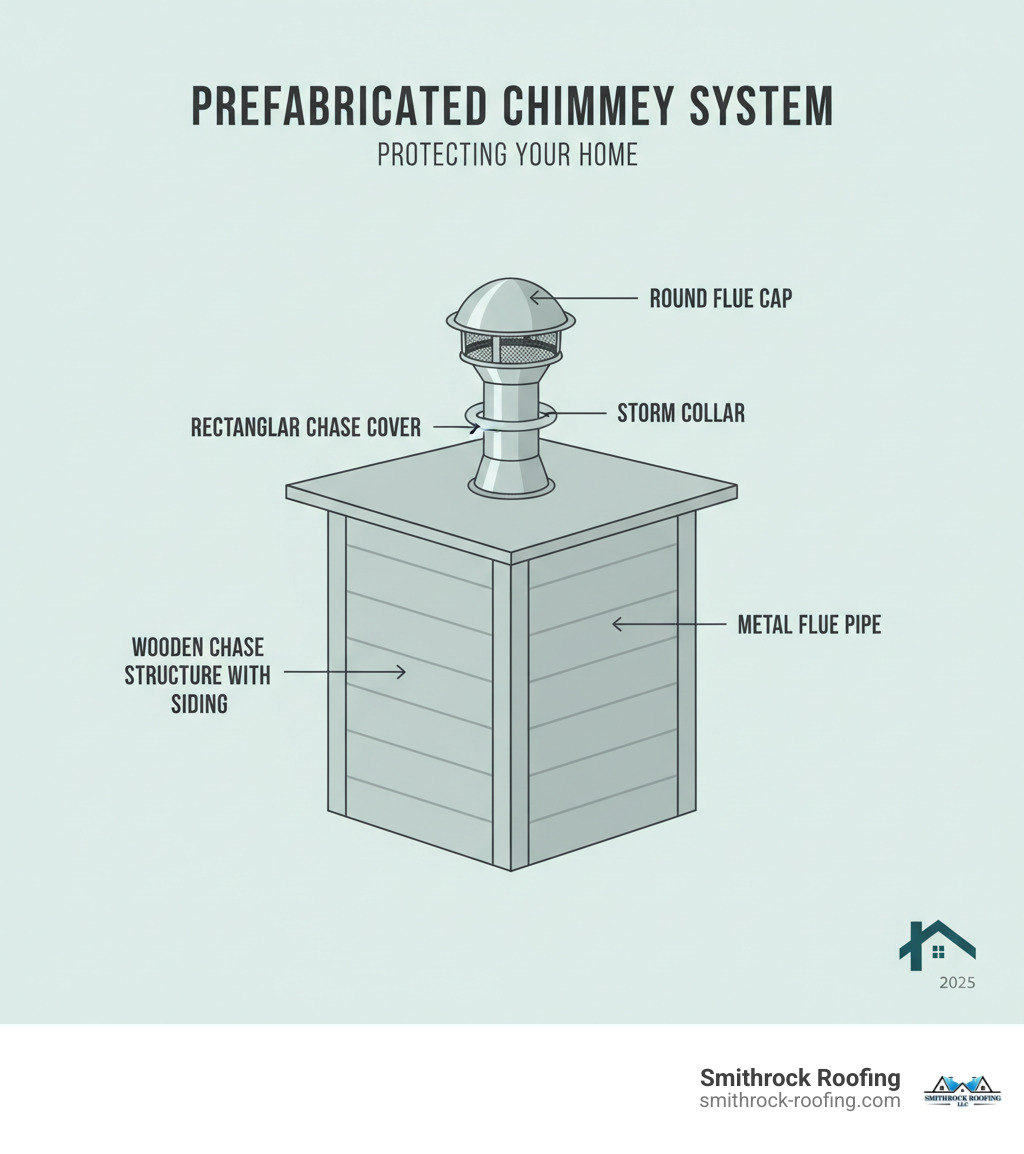

A prefabricated chimney is a complete, UL-listed fireplace and venting system that is manufactured in a factory and assembled on-site. Its core component is a high-tech metal flue pipe, typically with a double or even triple wall. These multiple layers are not just for strength; they create air-cooled insulating channels that keep the outer wall of the pipe cool enough to be safely enclosed within a wooden structure. This is the key difference from a masonry chimney, which uses the sheer mass of brick and mortar to contain heat.

This metal flue is housed inside a wooden frame called a chase. The chase is essentially a hollow column, built with standard lumber and sheathing, that runs from the fireplace unit up through the roof. To the outside world, the chase is often finished with siding, stucco, or a thin brick/stone veneer to mimic the appearance of a traditional chimney. However, beneath this cosmetic exterior lies a wooden structure that is highly susceptible to water damage and rot if not perfectly protected.

Unlike a brick chimney that might only need a single cap over the flue opening, a prefabricated system requires a three-part defense to remain dry, safe, and functional. Each component has a distinct and non-negotiable role.

The Chase Cover: This is the most critical protective element. It is a large metal lid, custom-fabricated to fit the exact dimensions of the top of the wooden chase. It functions as a miniature roof for the chimney structure, designed to shed rain, snow, and ice away from the vulnerable wood framing below. A quality chase cover is sloped for positive drainage, has a drip edge to prevent water from curling back underneath, and features a “skirt” that hangs over the sides to shield the top edges of the chase from wind-driven rain. Without a sound, leak-proof chase cover, water will inevitably saturate the wooden chase, leading to rot, mold, and catastrophic structural failure.

The Flue Cap: This is the smaller, typically round cap that sits directly on the metal flue pipe where it terminates above the chase cover. Its primary jobs are to keep rainwater from pouring directly down the flue pipe (which can rust out the fireplace), to block animals and debris from nesting or falling inside, and to act as a spark arrestor, preventing hot embers from landing on the roof. Most flue caps feature a mesh screen to perform this function while allowing smoke and gases to vent freely.

The Storm Collar: This small but mighty component is a cone-shaped metal ring that wraps tightly around the flue pipe and sits directly on top of the chase cover. Its sole purpose is to seal the circular gap between the flue pipe and the hole in the chase cover. Without a properly installed and sealed storm collar, rain would simply run down the side of the flue pipe, bypass the chase cover completely, and pour directly into the wooden chase, rendering the cover useless. This simple seal is a frequent point of failure in amateur installations, leading to devastating water damage that homeowners often misdiagnose as a roof leak.

Together, these three components—the chase cover, flue cap, and storm collar—form a complete, integrated system that is essential for the long-term health and safety of your prefabricated chimney.

Prefabricated chimney caps are not optional accessories; they are non-negotiable barriers that protect your home’s structure, safety, and value. They serve as the first and most important line of defense for your entire chimney system, keeping your home safe, dry, efficient, and compliant with many local fire codes.

An uncapped or improperly capped chimney chase is a gaping hole in your roof. Every time it rains, water pours directly into the wooden structure, saturating the framing and sheathing. This leads to wood rot, which compromises the structural integrity of the chase and can cause it to lean or even collapse. This persistent moisture can also seep downward, causing damage to your attic, ceilings, and interior walls. Homeowners often mistake these issues for complex Roof Leaks in Winston Salem: Prevention Tips for Homeowners, when the true culprit is a failed chase cover that costs a fraction of the resulting interior repairs. Furthermore, the damp, dark environment inside a leaking chase is a perfect breeding ground for toxic black mold, which can pose serious health risks. A properly installed chase cover and flue cap deflect all water, preventing these cascading problems and saving you from thousands of dollars in Roof Repair Services.

To raccoons, squirrels, birds, and even bats, an open chimney flue is a warm, sheltered, and ideal place to build a nest and raise a family. These nests, often made of highly flammable materials like twigs, leaves, and grass, create a dangerous blockage. This prevents smoke and lethal carbon monoxide from venting safely, potentially causing them to back up into your home. The nesting material itself is a severe fire hazard; sparks from your fireplace can easily ignite it, starting a chimney fire that can quickly spread to the rest of your house. A flue cap with a sturdy mesh screen is an impenetrable barrier that effectively blocks animals and falling debris, ensuring your flue remains clear, safe, and functional. It’s important to note that some species, like Chimney Swifts, are federally protected, so preventing them from nesting is far easier than dealing with them once they’ve moved in.

A wood-burning fire naturally produces sparks and hot embers that travel up the flue. Without a cap, these embers can be carried by the wind and land on your roof, a neighbor’s roof, or nearby dry grass and trees, posing a significant fire risk. The mesh screen on a flue cap acts as a spark arrestor, catching and extinguishing these embers before they can escape. In many areas, especially those prone to wildfires, spark arrestors are required by local building and fire codes.

High winds blowing across your roof can create pressure differentials that force air down your chimney flue. This phenomenon, known as downdraft, pushes smoke, soot, and unpleasant odors back into your living space. Many flue caps are specifically designed with a shape that deflects wind and promotes a consistent upward draft, helping to ensure your fireplace draws properly and your home remains smoke-free, even on gusty days.

An open chimney flue is essentially a hole in your home’s thermal envelope, acting like a window left open year-round. During the winter, your expensive heated air escapes up the chimney, while in the summer, your cooled indoor air is lost. A flue cap helps to reduce this airflow, mitigating energy loss and leading to tangible savings on your heating and cooling bills over time. For maximum efficiency, some homeowners even pair a standard cap with a top-sealing damper, which can be closed tightly when the fireplace is not in use.

A rusted, dented, or missing chimney cap is an eyesore that detracts from your home’s curb appeal. It signals neglect to potential buyers and home inspectors. A new, well-maintained prefabricated chimney cap system, especially one made from a premium material like stainless steel or copper, provides a clean, sharp, and finished look. It enhances your home’s appearance and communicates that the property is well-cared-for, which can positively impact its overall value.

When you’re shopping for prefabricated chimney caps, you’re not just looking for something that fits—you’re making a long-term investment in your home’s protection and appearance. The material you choose is the single most important factor determining how long your cap will last, how it will perform, and whether you’ll be replacing it in five years or fifty. Let’s walk through your options so you can make an informed choice for your home, climate, and budget.

Your chase cover and flue cap are exposed to the harshest conditions imaginable: relentless UV radiation, driving rain, heavy snow loads, ice, and extreme temperature fluctuations. The material must be up to the task.

Galvanized Steel: This is the most common material used by builders because it’s the cheapest. It is regular steel that has been hot-dipped in a zinc coating to provide a thin layer of rust protection. The problem is that this coating is fragile. It can be scratched during installation, and it naturally wears away over time due to acid rain and sun exposure. Once the zinc is compromised, rust begins immediately. In most climates, you can expect a galvanized cover to show rust stains within 3-5 years and require replacement within 5-10 years. While it offers a low upfront cost, it is by far the most expensive option in the long run due to repeated replacement costs and the high risk of water damage from premature failure.

Stainless Steel: This is the industry standard for any quality, long-term replacement. Approximately 85% of reputable replacement chase covers are made from 22-gauge 304 stainless steel. The gauge number indicates thickness—the lower the number, the thicker and more durable the metal. Builder-grade caps are often a flimsy 26 or 28-gauge. Stainless steel contains chromium, which makes it inherently resistant to rust and corrosion. A well-made stainless steel cover can easily last 20-30 years or more with zero maintenance. For homes in coastal areas exposed to salt spray, an upgrade to 316-grade (marine-grade) stainless steel is recommended for its superior corrosion resistance. While the upfront cost is higher than galvanized, its longevity and reliability make it the most cost-effective and responsible choice for homeowners.

Copper: This is the premium, lifetime choice. A copper chase cover is a work of art that can last for 50 years or more, often outliving the roofing material itself. Copper is naturally impervious to rust and is incredibly durable. Over time, it develops a distinctive and beautiful blue-green patina through oxidation, which not only protects the metal but also adds a look of timeless elegance to a home. It is the most expensive material, but it is a true “buy it once, cry once” investment that offers unparalleled durability and aesthetic appeal, making it a popular choice for high-end custom homes.

Aluminum: Aluminum is a lightweight, mid-range option. Its primary benefit is that it is naturally rust-proof. However, it is a much softer metal than steel or copper, making it more susceptible to denting from hail and damage from falling branches. It can also be prone to cracking at the seams over time. For an aesthetic choice, aluminum can be painted or powder-coated in various colors. Powder coating provides a much more durable finish than simple paint. While a viable option, it doesn’t offer the same robust, long-term durability as stainless steel.

Beyond material, the design and style of your cap system play a role in both function and curb appeal.

Chase Covers: The most common design is the standard flat chase cover with cross-brakes. The cross-brakes are subtle diagonal ridges pressed into the metal. They are not for decoration; they add significant strength and rigidity to the panel, preventing it from rattling or booming in the wind (a phenomenon called “oil canning”) and helping to shed water to prevent pooling. A quality cover will also have a skirt (the vertical side) with a hemmed edge or drip edge at the bottom. This reinforces the skirt and kicks water away from the side of the chase. The standard skirt height is 3 inches, which is appropriate for about 68% of chimneys.

Custom Shrouds: For homeowners seeking a more architectural or decorative look, a custom shroud is the answer. A shroud is a decorative housing that is installed over the functional chase cover and flue pipe. It can be designed in countless styles—such as a hip-and-ridge roof, standing seam metal, or a curved bell-top—to complement your home’s specific architectural style. Shrouds conceal the less-attractive flue pipes and provide a substantial, high-end finish to the chimney. They are fabricated from the same materials, with stainless steel and copper being the most popular choices for their beauty and longevity.

Flue Caps: The flue cap itself also comes in several styles. The standard round cap with a flat or slightly domed lid and mesh sides is the most common. For homes in windy areas experiencing downdrafts, a wind-directional cap (with a rotating hood) or a turbine cap can be installed. These use the wind’s power to actively draw smoke up and out of the flue. For multi-appliance chimneys, a single large multi-flue cap can be used to cover two or more pipes under one roof.

When 89% of prefabricated chimneys need just one hole for the flue pipe, the design is straightforward. However, for multiple penetrations, custom fabrication is essential to ensure every opening is perfectly placed and protected.

The right combination of material and style transforms your prefabricated chimney caps from a purely functional necessity into a feature that protects your home while enhancing its appearance. Whether you choose the reliable simplicity of a stainless steel flat cover or the timeless elegance of a copper custom shroud, you’re making an investment in your home’s future—and that’s something worth getting right.

A proper fit and a flawless installation are just as critical as the material you choose for your prefabricated chimney caps. An ill-fitting cap or a poorly sealed installation will fail, channeling water directly into the areas you’re trying to protect and potentially causing more harm than no cap at all. This is a job where precision is everything.

Safety is the absolute top priority. Working on a roof is inherently dangerous and should not be attempted by anyone without the proper experience, equipment, and comfort with heights. We strongly recommend hiring a professional for this task. If you choose to proceed, you must take extreme precautions:

For a visual overview of the process, this helpful video on chase cover installation demonstrates the key steps, but remember that watching a video is no substitute for professional experience.

Accurate measurements are the foundation of a leak-proof chase cover. Your cover will be custom-fabricated, so the mantra is “measure twice, cut once.”

This guide is a summary for informational purposes. For guaranteed, warrantied results, we recommend our professional Chimneys services.

A meticulous, professional installation ensures your prefabricated chimney caps will perform as designed, preventing water damage and the need for future Roof Repair Services.

Your prefabricated chimney caps are your home’s frontline defenders against the elements, but they are not invincible. Understanding their expected lifespan, performing routine maintenance, and knowing how to spot common problems is key to ensuring they continue to protect your home and preventing small issues from turning into major, expensive structural damage.

The longevity of your chimney cap system is directly tied to three factors:

Common problems to watch for during an inspection include:

Preventative maintenance is simple and can save you thousands in repairs. We recommend an annual inspection.

Annual Inspection Checklist:

When to Repair vs. When to Replace:

A professional Roof Inspection or chimney sweep service is the best way to ensure a thorough evaluation. The health of your chimney is intrinsically linked to your entire Residential Roofing system, and proactive maintenance is the most effective strategy to protect your investment.

As experts in chimney protection, we’ve answered thousands of questions from homeowners. Here are clear, straightforward answers to some of the most common ones regarding prefabricated chimney caps.

This is the most common point of confusion. A prefabricated chimney requires both components to be fully protected. They have two very different jobs:

Think of it this way: the chase cover protects the chimney’s house, and the flue cap protects the chimney’s pipe.

While it is technically possible for a highly experienced DIYer with the right safety equipment, we strongly advise against it for two main reasons. First, the safety risks associated with working on a roof are significant. Second, and more importantly, achieving a perfect, 100% watertight seal is extremely difficult for an amateur. The seal around the storm collar is especially tricky. A tiny, unseen gap in the sealant will funnel water directly into your chimney chase, leading to thousands of dollars in wood rot and interior water damage. Professional installation from a service like our Chimneys team ensures the job is done safely and correctly, and it typically comes with a warranty against leaks, providing peace of mind that your home is truly protected.

Absolutely, yes. It is one of the smartest investments you can make in your home. A cheap galvanized steel cover might save you a few hundred dollars upfront, but it is a temporary solution that is guaranteed to rust and fail, usually within 5-10 years. When you factor in the cost of the inevitable second replacement, plus the significant financial risk of water damage when the galvanized cover fails, it becomes a much more expensive option in the long run.

A quality stainless steel chase cover is a permanent solution. It will not rust, it will withstand the elements, and it will reliably protect your home for 20 years or more. You are paying for durability, reliability, and the “install it and forget it” peace of mind that comes with a superior, long-lasting product.

The cost can vary widely based on the size of your chimney, the material you choose, and local labor rates. For materials alone, a small galvanized cover might be a few hundred dollars, while a stainless steel setup for the same chimney could be $500-$900, and copper could be $1,500 or more. Professional installation typically adds several hundred dollars to the total cost but includes the security of a proper, warrantied seal. While it’s a significant investment, it is far less expensive than repairing a rotted chimney chase and the associated interior water damage.

Yes, you absolutely do. The primary function of the chase cover and flue cap is to protect your home from water and wildlife, which are constant threats whether you use the fireplace or not. An uncapped chimney is an open invitation for rain to rot the structure and for animals to move in, creating unsanitary conditions and blockages. The cap system is a crucial part of your home’s exterior envelope, not just a fireplace accessory.

Your home’s protection is a complete system, and the prefabricated chimney caps are a vital part of that defense. These components work tirelessly to deflect rain, block pests, arrest sparks, and improve energy efficiency. Without a quality chase cover and flue cap, your home is vulnerable to water damage, fire hazards, and costly repairs.

The key takeaways are simple: choose a durable material like stainless steel for long-term value, take accurate measurements for a perfect fit, and ensure proper, watertight installation. A well-made and correctly installed cap system is not an accessory; it’s a crucial investment in your home’s safety and structural integrity.

At Smithrock Roofing, we have seen the expensive damage that can result from a failed or missing chimney cap. We help homeowners across Winston-Salem NC, King NC, Clemmons NC, and surrounding areas secure their homes with expert installation. If you need advice, custom measurements, or a professional installation that guarantees a perfect seal, we are here to help.

Protect your investment and enjoy your fireplace with confidence. For comprehensive services and the expertise your home deserves, explore our Chimneys services page today.

Smithrock Roofing © Copyright 2025 • All Rights Reserved • Privacy Policy • Maintained by Mongoose Digital Marketing