Why Fireplace Cap Installation Is Essential for Home Protection

A fireplace cap installation is one of the most critical and cost-effective home maintenance tasks you can undertake. Often overlooked, a chimney cap (also known as a fireplace cap) serves as your home’s primary shield against a barrage of potential threats, including persistent water damage, destructive animal intrusions, and dangerous fire hazards. It is a small investment that provides immense protection for your chimney system and your entire home.

Without a cap, your chimney is an open vulnerability. Rain and snow pour directly into the flue, leading to thousands of dollars in damage. This moisture saturates the masonry, rusts the damper assembly, deteriorates the flue liner, and can eventually seep into your home’s walls and ceilings, causing structural rot and promoting toxic mold growth. Furthermore, an open flue is an open invitation to wildlife. Raccoons, squirrels, and birds can build large nests that not only block the chimney—creating a fire hazard and pushing carbon monoxide back into your home—but also introduce parasites and diseases. Finally, a cap acts as a spark arrestor, preventing hot embers from landing on your roof and starting a devastating fire.

Quick Installation Overview:

- Measure your flue: Accurately record its length, width, and height.

- Choose the right cap: Select a single-flue or multi-flue cap made from a durable material suited to your climate.

- Gather safety gear: Prioritize safety with a sturdy ladder, a safety harness, and non-slip shoes.

- Position and secure: Attach the cap correctly using the appropriate screws and sealant for your flue or crown.

- Test the fit: Ensure the cap is firmly secured with adequate clearance for proper airflow.

The installation process differs for single-flue and multi-flue chimneys. While a DIY installation might seem to save on labor costs (professional installation typically ranges from $300-$500), it is a task that carries significant risk. Working at heights requires specialized safety equipment and experience. An improper installation can lead to a cap blowing off in a storm, persistent leaks, structural damage, or even fires, making professional help a wise and secure investment.

I’m Jordan Smith of Smithrock Roofing. With over 15 years in exterior construction, I’ve seen how a proper fireplace cap installation prevents catastrophic, expensive repairs and provides homeowners with invaluable peace of mind.

Understanding Chimney Caps: Purpose, Materials, and Types

A chimney cap is a protective cover engineered to sit atop your chimney, shielding the flue opening from external threats while allowing smoke and combustion gases to ventilate safely. Its multi-functional design is crucial for chimney longevity and home safety. Here are its primary functions in greater detail:

- Prevent Water Damage: A cap is the single most effective defense against water infiltration. Rain and snow entering the flue can cause a cascade of problems. Water mixes with creosote to form a highly corrosive acid that eats away at metal and masonry liners. It accelerates the freeze-thaw cycle in bricks and mortar, where absorbed water freezes, expands, and causes the masonry to crack and flake (a process called spalling). This leads to costly tuckpointing or even a complete chimney rebuild. Furthermore, moisture can rust out the damper assembly, damage the firebox, and seep into your home, causing water stains and structural damage.

- Block Animals and Debris: The cap’s mesh screening is a physical barrier against wildlife. Raccoons, squirrels, and birds seek out chimneys as safe, warm places to nest. Their nesting materials (twigs, leaves, and trash) are highly flammable and can cause a chimney fire. A nest can also completely block the flue, preventing smoke from escaping and forcing deadly carbon monoxide back into your home. Animal droppings accumulate, creating foul odors and harboring bacteria and parasites. It’s also important to note that some species, like chimney swifts, are federally protected, and removing their nests can be a legal issue, making prevention the best strategy.

- Increase Fire Safety (Spark Arrestor): The mesh screen acts as a spark arrestor, a critical safety feature for wood-burning fireplaces. It catches hot embers and sparks carried up by the draft, preventing them from landing on your roof, nearby trees, or your neighbor’s property. This is especially vital for homes with wood shake roofs or those located in wildfire-prone areas, where a single spark can lead to disaster.

- Stop Downdrafts: A well-designed cap helps manage airflow, preventing strong winds from creating downdrafts. A downdraft pushes cold air and smoke back down the chimney, filling your living space with soot and unpleasant odors. This not only creates a mess but also negatively impacts your home’s indoor air quality.

It’s important not to confuse a full chimney cap with a simple chimney pot or windscreen, which offer minimal protection and lack the comprehensive benefits of a proper, full-coverage cap.

Chimney Cap Materials and Their Impact

Choosing the right material for your fireplace cap installation is a balance of durability, budget, and aesthetics. Each option offers distinct advantages.

| Material | Average Lifespan (Years) | Cost (Approx. for standard size) | Pros | Cons |

|---|

| Galvanized Steel | 5-15 | $56-$74 | Most affordable initial cost, widely available for standard flue sizes. | Prone to rust and corrosion, especially in wet or coastal climates. Rust can stain chimney masonry. Requires more frequent replacement. |

| Stainless Steel | Lifetime (50+ years) | $79-$125 | Excellent durability, highly resistant to rust and corrosion, great long-term value. | Higher upfront cost than galvanized steel. |

| Aluminum | Lifetime (50+ years) | $75-$150 | Lightweight, completely rust-proof, ideal for prefab chimneys and coastal areas. | Can be less rigid than steel and more susceptible to denting from hail or falling branches. |

| Copper | Lifetime (100+ years) | $376-$446 | Premium aesthetic, extremely durable, rust-proof, develops a beautiful blue-green patina over time. | Highest upfront cost. The distinctive patina may not suit all home styles. |

- Galvanized Steel: This is the most budget-friendly choice for an immediate fix. However, its zinc coating wears away over time, leading to rust that can stain your chimney. It has the shortest lifespan and should be considered a temporary solution, requiring regular inspection and replacement every 5-15 years.

- Stainless Steel: Our most recommended material for its balance of cost and performance. It is highly resistant to rust and warping and will last for the life of your chimney system. Look for high-quality grades like 304 or, for coastal areas with salt spray, marine-grade 316 stainless steel for maximum corrosion resistance.

- Aluminum: Lightweight and completely rust-proof, aluminum is an excellent choice, particularly for prefabricated metal chimneys where weight is a concern. Its resistance to corrosion also makes it a strong contender in coastal regions.

- Copper: The premium choice for ultimate durability and best curb appeal. Copper caps are a statement piece that develops a beautiful, classic patina over time. This patina is a natural protective layer that ensures the cap can last for a century or more, often outliving the home itself.

For homeowners planning to stay in their home long-term, we strongly recommend investing in stainless steel or copper. The initial savings from a galvanized cap are often negated by future replacement costs and the potential for damage if it fails.

Common Types of Chimney Caps

The type of cap you need depends on your chimney’s structure.

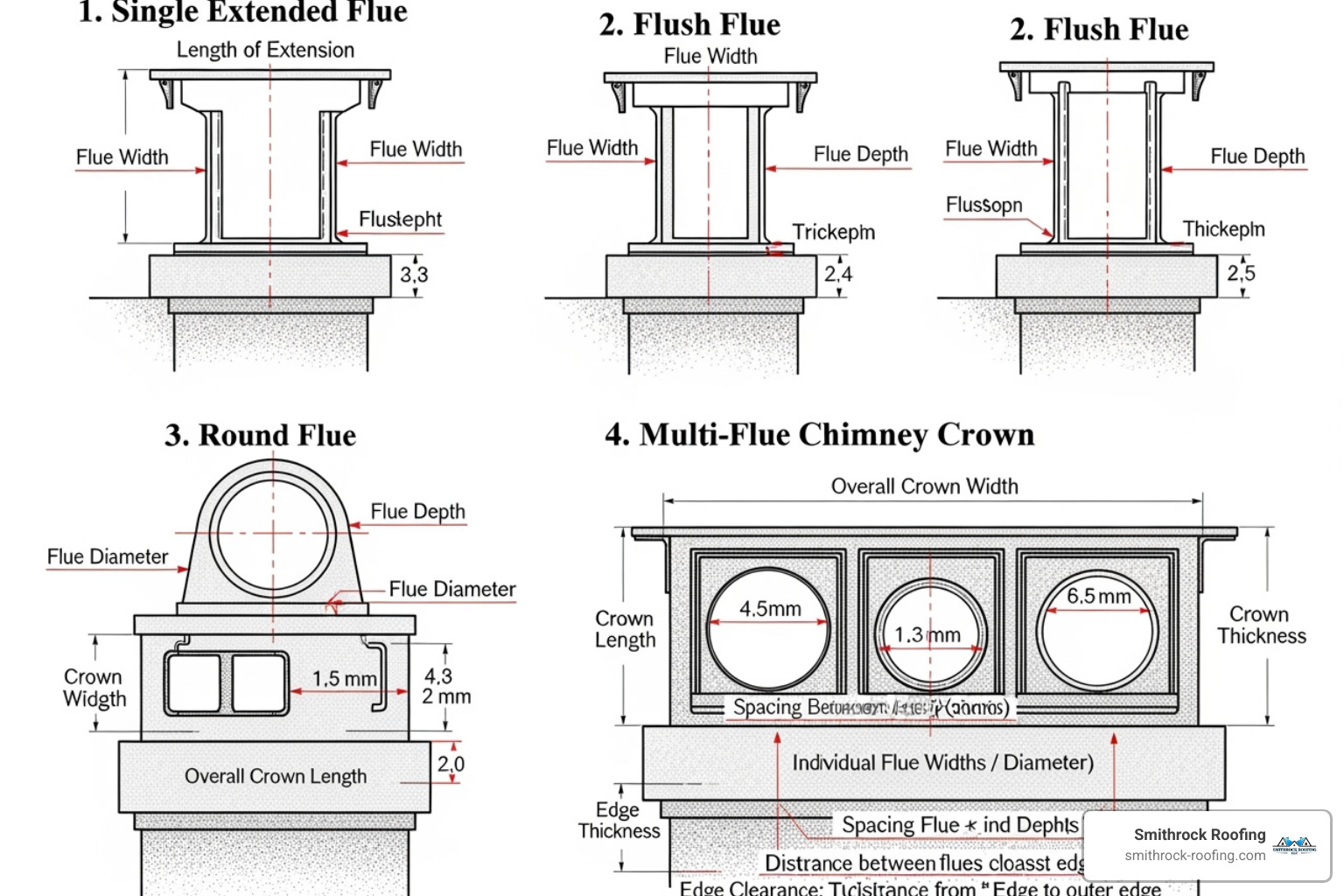

- Single-Flue Caps: The most common type, designed to attach directly to a single flue tile that extends above the chimney crown. They come in several mounting styles, including slip-in models that fit inside the flue, and clamp-on or screw-set models that attach to the outside of the flue tile.

- Multi-Flue Caps: A single, large cap designed to cover the entire chimney top, protecting two or more flues simultaneously. This often provides a cleaner, more uniform look and can be more cost-effective than installing multiple single caps. It also offers superior protection for the chimney crown itself.

- Top-Mount Caps (or Crown-Mount Caps): These caps mount directly to the chimney crown rather than the flue. They are the ideal solution for chimneys where the flues do not extend above the crown or when the crown itself has minor cracks that need protection from direct rainfall.

- Specialty Caps: This category includes decorative caps (often made of copper with ornate designs), draft-increasing caps (which use venturi effects or turbines to improve airflow in problematic chimneys), and wind-directional caps that pivot to block wind from any direction, preventing downdrafts.

Every quality cap must include a spark arrestor mesh screen with openings typically between 3/8″ and 5/8″ to balance spark protection with proper ventilation. The key to a successful fireplace cap installation is matching the right type and material to your specific chimney, budget, and local climate.

Fireplace cap installation requires working at heights, a task that carries inherent risks. While it can be a rewarding DIY project for an experienced homeowner, safety must always be the absolute top priority. The DIY risks are significant and include falls from ladders or roofs, electrical shock from nearby power lines, and improper installation that leads to water leaks or a cap detaching in high winds. A poorly executed DIY job can easily cost far more in property damage or medical bills than a professional installation.

Success hinges on three pillars: uncompromising roof safety, using the proper equipment, and taking carefully accurate measurements. A cap must fit perfectly to be effective, which is why the importance of custom sizing cannot be overstated. A generic, ill-fitting cap is little better than no cap at all.

Never attempt this project without the right equipment. Using inadequate tools or forgoing safety gear can lead to serious injury and a failed installation.

Safety First Checklist:

- Sturdy Extension Ladder: Ensure it extends at least 3 feet above the roofline for safe transitioning. Use a ladder stabilizer to prevent sideways movement.

- Safety Harness and Rope: This is non-negotiable for any roof with a steep pitch (generally anything over a 4/12 pitch) or for multi-story homes.

- Non-Skid Footwear: Wear soft-soled, high-traction shoes for a secure grip on the roof surface.

- Heavy-Duty Work Gloves: Protect your hands from sharp metal edges and rough masonry.

- Safety Glasses: Shield your eyes from debris when cleaning the chimney or drilling.

- Weather Awareness: Never work on a wet, icy, or windy day.

- Spotter: Have a person on the ground to stabilize the ladder, pass tools, and call for help if needed.

Installation Tools:

- Tape Measure: For taking precise measurements.

- Power Drill with Masonry Bits: For drilling into the concrete crown for top-mount caps.

- Screwdriver or Nut Driver: To tighten the cap’s fasteners.

- Caulking Gun and Sealant: For applying construction adhesive or high-temperature silicone.

- Stiff-Bristled Wire Brush: To thoroughly clean the chimney crown or flue before installation.

If you are uncertain about working on your roof or lack any of this equipment, our team has the professional-grade gear and extensive safety training to handle the job safely and efficiently.

More info about our Roof Repair Services

How to Measure Your Chimney for a Perfect Fit

Precise measurements are the foundation of a successful installation. An ill-fitting cap will fail to protect your chimney and may even restrict airflow. Always measure twice before ordering.

Many masonry flues have standard dimensions (e.g., 9″x9″, 9″x13″, 13″x13″). However, if your measurements are non-standard, you will need a custom-fit cap. Taking photos of your chimney top with the tape measure in place can be very helpful when ordering.

The Step-by-Step Guide to Your Fireplace Cap Installation

With your measurements taken, safety gear on, and the correct cap in hand, you are ready for the fireplace cap installation. The process is methodical and requires careful attention to detail to ensure a secure, watertight fit. The core steps involve a pre-installation inspection, thoroughly cleaning the crown, correctly positioning the cap, securing the cap firmly, and sealing the base where necessary.

Installing a Single-Flue Chimney Cap

Single-flue caps are generally the most straightforward to install as they attach directly to the protruding flue tile.

- Pre-Installation Inspection: Before you begin, carefully inspect the clay flue tile for any cracks, chips, or signs of deterioration. If the tile is damaged, it may not be strong enough to support a screw-mounted cap and could crack further during installation. In this case, professional repair is needed first.

- Clean the Flue Tile: Use a stiff wire brush to thoroughly remove any soot, debris, or loose mortar from the top and sides of the flue tile. A clean surface is essential for a secure fit.

- Position the Cap: Test fit the cap by carefully lowering it onto the flue tile. Ensure it is centered and sits level. The fit should be snug but not forced.

- Secure the Cap: The method depends on the cap’s design:

- Screw-Set Caps: These have screws on the base that tighten directly against the flue tile. Hand-tighten each screw first to ensure even pressure, then use a screwdriver to secure them firmly. A quarter-turn past hand-tight is usually sufficient. Do not overtighten, as this is the most common cause of cracked flue tiles.

- Clamp-On Caps: These use a band that wraps around the flue and is tightened with a bolt. This design distributes pressure more evenly and is often a safer choice for older clay tiles.

- Final Check: Gently tug on the cap from different sides to ensure it is completely secure and does not wobble.

Installing a Multi-Flue or Top-Mount Chimney Cap

These caps mount to the chimney crown and require more precision to create a weatherproof seal.

- Pre-Installation Inspection: Examine the chimney crown for cracks, crumbling concrete, or low spots where water could pool. Minor cracks can be sealed, but a severely damaged crown may need to be repaired or rebuilt before installing the cap.

- Clean the Crown: Thoroughly sweep the chimney crown to remove all leaves, loose mortar, and any other debris. The surface must be clean and dry for the sealant to adhere properly.

- Position and Mark: Center the cap over the flues. Ensure there is at least one inch of clearance from the cap’s base to the crown’s outer edges. Use a pencil or marker to mark the locations for the mounting screws through the holes in the cap’s base flange.

- Drill Pilot Holes: Remove the cap. Using a masonry bit that is slightly smaller in diameter than your mounting screws, drill pilot holes about 1.5 inches deep into the crown at your marked locations. This prevents the concrete from cracking when you drive the screws.

- Apply Sealant: Apply a continuous, generous bead of 100% silicone or high-grade polyurethane construction adhesive to the crown along the line where the cap’s base will sit. Do not leave any gaps in the bead, as this is what creates the vital watertight seal.

- Secure the Cap: Carefully place the cap onto the bead of sealant, aligning the mounting flanges with your pilot holes. Drive in the masonry screws, tightening them evenly. Alternate between screws to ensure even pressure and prevent the base from warping.

- Final Check: Inspect the sealant bead around the base of the cap. If there are any gaps, apply a little more sealant to tool it smooth. The cap should feel completely solid and immovable.

DIY vs. Hiring a Professional

The decision to DIY a fireplace cap installation or hire a professional hinges on a realistic assessment of your skills, the tools you have available, and the specific characteristics of your chimney and roof. A simple, screw-on single-flue cap on a low-slope, single-story roof might be a feasible DIY project for a confident homeowner. However, the complexity and risk increase significantly with multi-flue caps, steep roofs, multi-story homes, or any signs of pre-existing chimney damage. In these cases, the project skill level demands professional intervention.

The Risks of DIY Fireplace Cap Installation

While saving on labor costs is tempting, the potential downsides of a DIY attempt can be severe and costly:

- Personal Injury: Falls from ladders or roofs are a leading cause of serious injury for homeowners. Professionals use specialized fall protection equipment and are trained to steer roofs safely. The risk of a life-altering injury far outweighs the few hundred dollars saved on labor.

- Improper Installation: A cap that is not perfectly centered, level, and secured can create a host of problems. It may fail to provide adequate protection, restrict airflow and cause draft issues, or worse, become a dangerous projectile in a high-wind storm, capable of damaging your property, your neighbor’s property, or vehicles.

- Creating Leaks: The most critical part of a top-mount installation is creating a perfect, watertight seal. Using the wrong type of sealant, applying it incorrectly, or failing to prepare the surface can lead to persistent water leaks that cause slow, hidden damage to your chimney and home interior for years.

- Damaging the Chimney: Overtightening screws can easily crack a brittle clay flue tile, a repair that can cost thousands of dollars. Improperly drilling into a concrete crown can cause it to crack and crumble, turning a simple cap installation into a major masonry repair project.

- Voiding Warranties: Many homeowner’s insurance policies or product warranties may not cover damage that results from improper, uncertified DIY work. A professional installation provides documentation and ensures compliance.

Professional Fireplace Cap Installation: Who to Hire

It is always time to call a professional if your roof is steep, you are uncomfortable with heights, or you observe any signs of chimney damage. A professional can not only install the cap correctly but also identify and address underlying issues.

- Chimney Sweeps: These are certified specialists in all things chimney-related. They have deep knowledge of chimney anatomy, ventilation science (draft), and local building and fire safety codes. They are an excellent choice if you also need a chimney cleaning or internal inspection.

- Roofing Contractors: Companies like Smithrock Roofing possess extensive experience working safely at heights and are experts in how the chimney and roof systems integrate. We are uniquely qualified to identify and repair related issues like damaged flashing, which is a common source of leaks around the chimney base.

- Masonry Contractors: If your chimney shows significant signs of damage—such as a crumbling crown, widespread cracked bricks, or deteriorating mortar joints (tuckpointing needs)—a masonry specialist is the best choice. They can perform the necessary structural repairs before the cap is installed.

Our team serves communities across North Carolina, including Winston-Salem, and we combine roofing and chimney expertise to provide a holistic solution that ensures your entire system is safe, secure, and weatherproof.

Roofing Contractors in Winston Salem

Signs Your Existing Chimney Cap Needs Replacement

Inspect your chimney cap annually from the ground with binoculars, or as part of a professional roof inspection. Here are clear signs it’s time for a replacement:

- Visible Rust or Corrosion: For galvanized steel caps, rust is a sign the protective coating has failed. Rust streaks running down your chimney are an eyesore and an indicator that the cap itself is thinning and may have holes.

- Holes, Tears, or Warped Mesh: Damaged mesh compromises the cap’s two most important functions. It allows animals to enter and fails to act as a spark arrestor, dramatically increasing your fire risk.

- Bent or Damaged Frame: Damage from falling tree limbs, hail, or severe wind can warp the cap’s frame. This can break the seal with the crown, loosen the mounting, and affect its ability to shed water properly.

- Loose Fit: If the cap has shifted, wobbles, or appears crooked, its fasteners have failed. It is a significant hazard and must be secured or replaced immediately before it blows off.

- Water Stains in the Firebox or on Ceilings: This is a definitive sign that your cap (or chimney flashing) is failing and water is penetrating deep into the system.

- Evidence of Animal Entry: If you hear animal noises, find droppings in the firebox, or see nesting material, your cap is no longer providing protection.

Cost Considerations for Chimney Caps

While a fireplace cap installation has an upfront cost, it should be viewed as a critical investment in preventative maintenance. The total budget includes the material cost of the cap itself and the labor for a professional installation, which often includes a valuable chimney inspection. This one-time expense protects you from future problems that are exponentially more expensive to fix.

Breaking Down the Costs

The final price of a chimney cap project is influenced by its material, size, type, and the complexity of the installation.

- Material Costs: As detailed earlier, the cap itself can range from $56 for a basic galvanized steel model to over $446 for a decorative copper cap. Stainless steel offers the best value, typically costing between $79 and $125 for a standard size. Custom-sized or specialty caps will cost more.

- Professional Installation Labor: The average labor cost for a straightforward installation is around $200 to $400. This fee covers the professional’s time, specialized tools, safety equipment, and expertise.

Factors That Can Increase the Total Project Cost:

- Roof Accessibility: A steep-pitched roof or a multi-story home requires more time and advanced safety equipment (like harnesses and scaffolding), which increases labor costs.

- Chimney Repair Needs: If an inspection reveals underlying issues, they must be addressed. This is the most common reason for a higher total cost. These repairs can include:

- Crown Repair/Rebuild: Sealing cracks might cost a few hundred dollars, but rebuilding a crumbling crown can cost $1,000 to $3,000.

- Tuckpointing: Repointing failing mortar joints to stabilize the chimney structure can range from $500 to $2,500 or more, depending on the extent of the damage.

- Flashing Repair: Repairing or replacing the metal flashing around the base of the chimney typically costs $300 to $1,000.

While these additional costs can be unexpected, addressing them during the cap installation is far more cost-effective than scheduling a separate, major repair later on.

The Long-Term Savings: A High-Value Investment

The upfront cost of a professional cap installation is minimal when compared to the enormous potential savings from preventing catastrophic damage.

- Preventing Water Damage: Repairing a water-damaged chimney system is a massive expense. A new flue liner can cost $2,500 to $7,000. Rebuilding a masonry firebox can exceed $5,000. A full chimney rebuild due to spalling and structural failure can cost $10,000 to $20,000. A chimney cap is the best defense against these scenarios.

- Avoiding Animal Removal and Cleanup: Professional removal of animals like raccoons can cost $300 to $600, not including the cost to repair any damage they caused inside the flue or damper. Removing a protected species like chimney swifts requires waiting for them to migrate, leaving your fireplace unusable for a season.

- Preventing Devastating Fire Damage: A cap’s spark arrestor feature helps prevent roof fires. The National Fire Protection Association reports that fire departments respond to over 20,000 chimney-related fires each year. The average cost of repairing home fire damage can easily exceed $70,000, making a sub-$500 chimney cap an incredibly wise safety investment.

- Improving Energy Efficiency: An open chimney flue is like leaving a window open all year round. A cap, in conjunction with a well-sealed damper, reduces the amount of heated or cooled air escaping from your home, leading to modest but consistent savings on your energy bills.

- Protecting Property Value: A well-maintained chimney with a quality cap is a positive feature for potential home buyers. Conversely, a stained, crumbling chimney without a cap is a major red flag during a home inspection.

When you analyze the cost-to-benefit ratio, few home improvements offer such a high level of protection for such a modest investment.

Get a Roof Estimate

Frequently Asked Questions about Fireplace Cap Installation

Here are detailed answers to the most common questions we receive about fireplace cap installation.

How long does a chimney cap last?

The lifespan of a chimney cap depends directly on its material, the local climate, and the quality of the installation.

- Material Lifespan: As a general guide, galvanized steel is a temporary solution lasting 5-15 years. In contrast, stainless steel and aluminum are considered lifetime materials, easily lasting 50 years or more. Copper is the most durable, often lasting over 100 years.

- Installation and Weather Impact: A securely installed cap will better withstand high winds and harsh weather. In coastal regions, the salt in the air accelerates corrosion, making a galvanized cap a particularly poor choice and elevating the value of stainless steel, aluminum, or copper.

Is a chimney cap required by code?

This varies by municipality. Some local building codes mandate chimney caps on all new construction, while others do not. However, spark arrestor requirements are very common, especially in wildfire-prone areas like California and other western states. These codes mandate a mesh screen with specific opening sizes to prevent embers from escaping.

Regardless of local regulations, every major fire safety organization, including the National Fire Protection Association (NFPA) and the Chimney Safety Institute of America (CSIA), strongly recommends installing a professionally fitted chimney cap on every active chimney. Building codes represent the minimum standard for safety; a cap represents the best practice for protecting your home. For technical guidance, refer to NFPA 211.

Can a chimney cap affect my fireplace’s draft?

A properly sized and installed chimney cap should improve, not hinder, your fireplace’s draft. If a cap negatively affects the draft, it is almost always due to improper sizing or installation.

- Proper Sizing and Airflow: A cap must be tall enough (hood at least 6 inches above the flue opening) and have sufficiently large mesh openings to avoid airflow restriction. A cap that is too small or sits too low can act like a lid, causing smoke to back up into your home.

- Preventing Downdrafts: A key benefit of a cap is preventing downdrafts, where wind is forced down the chimney. This not only stops smoke from entering the room but also prevents puffs of soot and bad odors when the fireplace is not in use.

What kind of maintenance does a chimney cap need?

A quality chimney cap requires very little maintenance. It should be visually inspected at least once a year from the ground. As part of your annual professional chimney sweeping and inspection, the technician will check the cap up close to ensure it is still secure, free of debris on the mesh, and shows no signs of damage or corrosion.

Yes, but you must use a cap specifically designed for that type of chimney. Prefabricated metal chimneys are often “air-cooled,” with a double or triple-wall construction. You need a cap that allows for proper airflow between these layers to prevent overheating. Using the wrong type of cap can create a fire hazard and will void the chimney’s UL listing and warranty.

Will a chimney cap stop all rain from getting in?

A standard chimney cap is extremely effective at stopping vertical rainfall, reducing moisture entry by over 95%. However, very strong, wind-driven rain can sometimes pass through the mesh screening on the sides. For homeowners in areas with frequent severe weather, specialty caps with wind baffles or a deeper hood design can offer even greater protection.

Conclusion: Your Home’s Most Valuable Protector

We’ve explored the critical details of fireplace cap installation, from understanding its vital functions and choosing the right materials to the specifics of measurement and installation. The single most important takeaway is that a chimney cap is not an optional accessory; it is an essential component of your home’s protective shield. It is your first and best line of defense against the relentless threats of water damage, the destructive intrusion of animals, and the ever-present danger of fire from stray sparks.

This small investment pays for itself many times over by preventing the need for enormously expensive repairs down the road. A quality cap protects your chimney’s masonry, liner, and damper assembly, preserving the integrity of the entire system. It ensures your fireplace can operate safely and efficiently, venting harmful gases out while keeping external threats from getting in.

While a DIY approach may seem tempting for the simplest of installations, safety must always be the paramount concern. The significant risks associated with working on a roof, combined with the precision required for a durable, weatherproof seal, make professional service the wisest and safest choice for the vast majority of homeowners. At Smithrock Roofing, our experienced team not only guarantees your cap is installed to the highest safety and performance standards but also inspects the surrounding chimney structure and flashing for any underlying issues, providing you with complete peace of mind.

Your chimney works hard to keep your family safe and warm. A professionally installed chimney cap is how you return the favor, protecting the vital structure that protects you.

Ready to secure your home with a professional fireplace cap installation? Contact our expert team today. We can help you select the perfect cap for your needs and ensure it’s installed correctly for decades of reliable protection.

Learn more about our chimney services and schedule your consultation today.