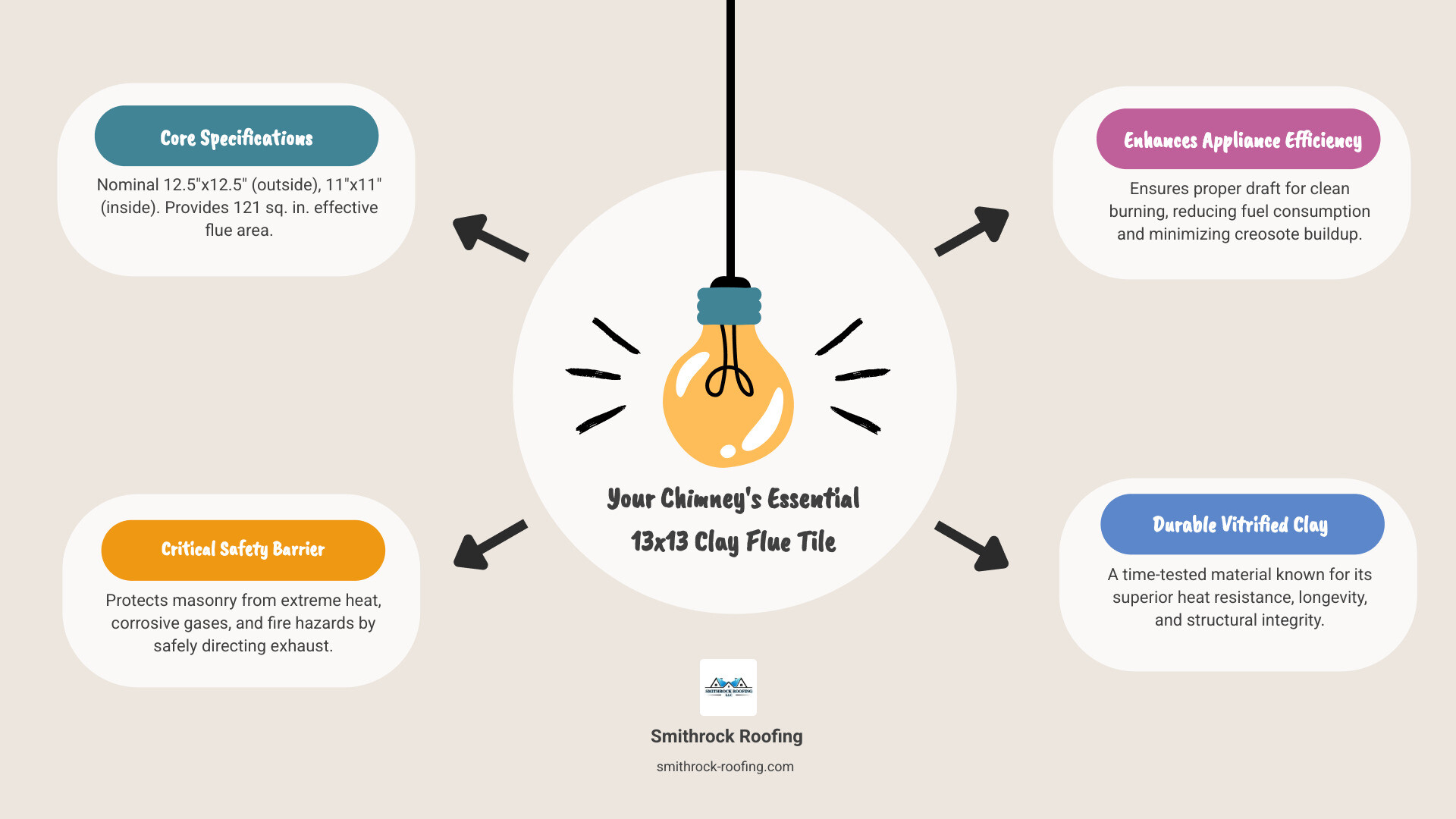

A 13×13 clay flue tile is a square, vitrified clay chimney liner with nominal outside dimensions of about 12.5″ x 12.5″ x 24″ and an inside opening of roughly 11″ x 11″, providing approximately 121 square inches of effective flue area. It weighs around 68 pounds and serves as the primary protective lining inside many traditional masonry chimneys, acting as a critical barrier between the fire’s byproducts and the home itself.

The term “vitrified clay” is key to understanding the tile’s function. Vitrification is an industrial process where specially selected clays and shales are fired in a kiln at extremely high temperatures (over 2000°F). This intense heat causes the clay particles to fuse and transform into a non-porous, glass-like substance. This process imparts several crucial properties:

Before the widespread adoption of clay liners in the early 20th century, chimneys were often unlined (“brick-and-mortar” only). This proved incredibly dangerous. The 13×13 clay flue tile, one of the most common sizes for residential fireplaces, performs several essential functions that modern building codes now mandate:

While these are nominal, they provide a baseline for understanding the component:

Correct flue sizing is a fundamental principle of chimney design, directly impacting draft, efficiency, and safety. For traditional open-hearth masonry fireplaces, the industry standard is the 1/10th rule. This rule states that the cross-sectional area of the flue should be at least one-tenth (1/10) of the area of the fireplace opening (width x height). With its 121 square inches of area, a 13×13 clay flue tile can typically support a fireplace opening up to 1,210 square inches (e.g., a 42-inch wide by 28-inch high opening).

A flue tile is only one part of a complete, safe chimney system. To ensure longevity and protection, you must also consider:

The designation “13×13” is a nominal size, a trade term that refers to the approximate outside dimensions for classification purposes. The actual, real-world measurements are slightly different, a critical detail for masons, chimney sweeps, and anyone ordering components like chimney caps.

Understanding the difference is crucial for proper construction and fitting of related parts.

These dimensions are governed by manufacturing standards like ASTM C315, which specifies the requirements for clay flue linings. However, slight variations can still exist between different manufacturers. For this reason, it is always best practice to physically measure the specific tile on-site before building or ordering a custom-fit chimney cap.

The single most critical specification for performance is the effective flue area—the usable interior space that dictates the chimney’s venting capacity.

This number is not arbitrary; it directly determines:

Draft is the pressure difference that causes air and smoke to flow up the chimney, a phenomenon known as the stack effect. It occurs because the hot, light gases inside the flue are more buoyant than the cold, dense air outside. Proper flue size is essential to harnessing this effect.

Flue Too Small:

Flue Too Large (A Common Problem):

The 13×13 clay flue tile strikes a balance for many traditional fireplaces, providing enough area for a large fire while being small enough to maintain the gas velocity and temperature needed for a good draft.

Flue performance is also critically dependent on the chimney’s overall height and its location relative to the roofline.

For over a century, vitrified clay has been the standard material for lining masonry chimneys. It remains a widely accepted, code-compliant solution that offers a unique combination of performance, durability, and tradition.

The 13×13 clay flue tile is a versatile component found in a variety of settings, each leveraging its specific properties.

This is the most common application. The 13×13 tile is perfectly suited for medium-to-large open-hearth fireplaces. Its 121-square-inch area aligns with the “1/10th rule” for typical fireplace openings, and its modular, rectangular form integrates seamlessly into the construction of a brick or block chimney. The clay liner and surrounding masonry work together as a system, with the masonry providing thermal mass and the clay providing a safe, smooth conduit for exhaust.

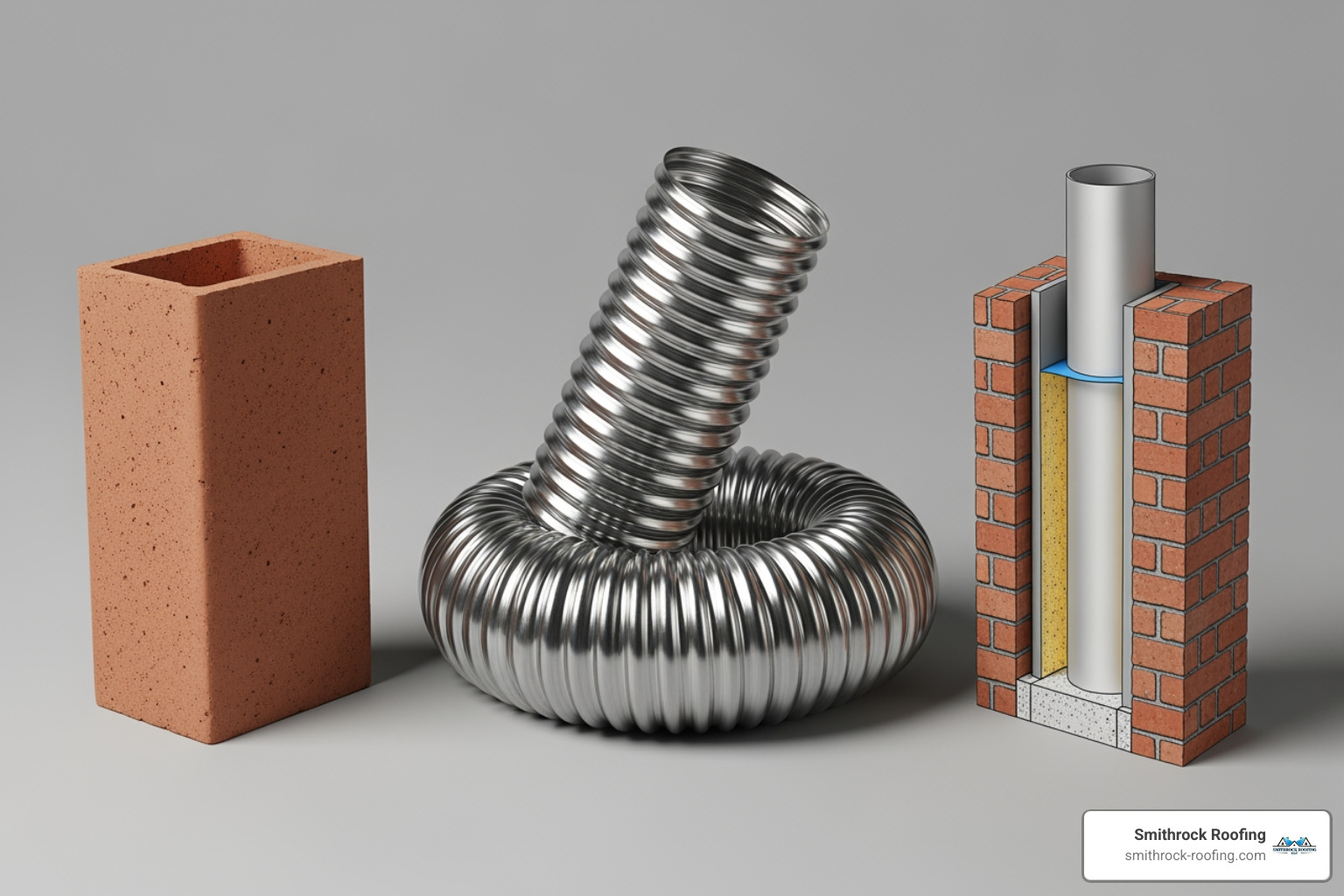

A common scenario involves installing a modern, high-efficiency wood stove or fireplace insert into an existing masonry fireplace. In these cases, the original 13×13 clay flue is almost always too large for the new appliance, which has a smaller exhaust collar (e.g., 6 or 8 inches). To ensure proper draft and prevent massive creosote buildup, a new, correctly sized stainless steel liner is installed inside the existing clay flue. The clay tile then serves as a protective outer chase, providing a crucial secondary barrier and maintaining the required clearance to combustibles.

The heat resistance and robust nature of clay tiles make them an excellent choice for outdoor fireplaces, fire pits, and brick pizza ovens. They can withstand the elements (when properly capped) and the intense, prolonged heat generated by these structures, offering a safe and durable venting solution.

Exceptional Durability: When installed correctly and protected from the elements by a proper crown and cap, a clay tile liner can last for many decades, often for the life of the house. Its primary enemies are water intrusion, severe thermal shock (like a chimney fire), and seismic events.

Superior Heat Resistance: Vitrified clay is designed to operate continuously at temperatures up to 1800°F and can withstand the short-term, intense heat of a chimney fire, which can exceed 2100°F. This prevents heat from transferring to the chimney structure and nearby combustible materials.

Inherent Chemical Resistance: The combustion of wood, oil, and gas creates acidic byproducts that condense in the flue. The non-porous, glass-like surface of a vitrified clay tile is highly resistant to these corrosive acids, preventing the material degradation that would occur in plain mortar or brick.

Cost-Effectiveness: While installation can be labor-intensive, the material cost of clay tiles is generally lower than that of stainless steel liners. Given its potential for a very long lifespan with minimal maintenance, it represents a sound long-term investment in a new-build chimney.

Clay flue liners excel in specific scenarios but are not a universal solution.

Clay is the ideal choice for:

Clay may be less suitable or require a different approach for:

For professional chimney evaluations and services in the Piedmont Triad area, it’s essential to consult with certified experts: chimney services.

While the standard 13×13 tile is the most familiar, understanding its variations and how it compares to other lining systems is crucial for making informed decisions about chimney safety and performance.

Standard Rectangular Tiles: This is the most common type. These are simply rectangular tubes with square-cut ends. During installation, they are stacked one on top of another, and the joints between them are sealed with a thin layer of high-temperature refractory mortar. The integrity of the liner depends heavily on the skill of the mason in creating perfect, fully sealed joints.

Socket Type (Bell and Spigot) Joints: A less common but superior design features a bell-shaped socket on one end and a narrower spigot on the other. The spigot of one tile fits securely into the bell of the tile below it. This design offers better alignment during stacking and creates a more robust, mechanically interlocking joint that is less prone to separation or gaps.

No single liner type is best for all situations. Each has distinct advantages and disadvantages.

| Feature | 13×13 Clay Tile | Stainless Steel Liner | Cast-in-Place Liner |

|---|---|---|---|

| Material | Vitrified clay | 316Ti or 304 stainless steel | Lightweight refractory cement |

| Installation | Sectional, built with chimney | Dropped or pulled through flue | Pumped around an inflatable form |

| Best Use | New masonry construction | Relining existing chimneys | Relining damaged/unusual flues |

| Lifespan | 50+ years (if maintained) | 15-30 years (lifetime warranty) | 50+ years (permanent) |

| Offsets/Bends | Not possible | Excellent (with flexible type) | Excellent |

| Insulation | None (relies on air gap) | Can be insulated (recommended) | Inherently insulating |

| Structural | Adds some rigidity | None (relies on chimney) | Adds significant strength |

This is the most common choice homeowners face, especially when upgrading an appliance.

Clay Advantages:

Stainless Steel Advantages:

Cast-in-place liners are a specialized solution for more complex problems.

Cast-in-Place Advantages:

Disadvantages: It is typically the most expensive relining method and requires highly specialized installers.

The shape of a flue has a significant impact on its aerodynamic efficiency.

For this reason, sizing rules are slightly different. The 1/10th rule is used for square or rectangular flues, while a more stringent 1/12th rule is often applied for more efficient round flues. A 12-inch round liner has a similar area to a 13×13 square liner but will generally perform better due to its superior shape.

While the 13×13 clay flue tile is a durable product, its safety and longevity are entirely dependent on proper installation and diligent, lifelong maintenance. Installation is not a DIY project and must be performed by qualified, experienced masons.

A safe and functional clay liner is built from the ground up with precision at every step.

Foundation and Smoke Chamber: The entire chimney structure, including the heavy clay liners (each 24″ section weighs nearly 70 lbs), must rest on a solid concrete footing. The smoke chamber, the critical transition area between the firebox and the flue, must be constructed with angled (corbeled) brickwork and parged smooth to ensure a seamless flow of smoke into the first flue tile.

Mortar Requirements: This is one of the most critical details. The joints between flue tiles must be sealed with refractory mortar, a specialized, non-water-soluble cement designed to withstand extreme temperatures and acidic moisture. Using standard masonry mortar will result in rapid joint failure, creating dangerous gaps in the liner.

Stacking and Jointing: Each tile is carefully set in a bed of refractory mortar. The key is to create a joint that is thin, uniform, and completely filled. As each tile is set, the mason must reach inside to smooth the joint, ensuring there are no protrusions (mortar “icicles”) that could disrupt airflow and collect creosote.

Clearances and Airspace: As the surrounding brick or block is built up around the liner, building codes mandate a minimum clearance to any combustible materials, such as wood framing. This is typically at least 2 inches of airspace from the chimney’s exterior masonry. This airspace acts as an insulator, preventing heat transfer.

The Chimney Crown: The chimney is finished with a crown, which is a capstone of solid, cast-in-place concrete. A proper crown is crucial for protecting the entire structure. It must be at least 4 inches thick, slope away from the flue liner to shed water, and overhang the chimney walls with a drip edge to prevent water from running down the face of the bricks. A flexible, high-temperature sealant must be used in the gap between the concrete crown and the clay tile to allow for thermal expansion and contraction.

All chimney construction and repair must adhere to strict codes for safety.

Annual Inspections: The NFPA 211 recommends that all chimneys, fireplaces, and vents be inspected annually. A certified chimney sweep will perform a visual check (Level 1 Inspection) or use a specialized camera system to scan the entire interior of the flue (Level 2 Inspection) to look for cracks, spalling, gaps in mortar joints, and hazardous buildup.

Regular Cleaning: The frequency of cleaning depends on usage. For a wood-burning fireplace, this means removing flammable creosote and soot. A rule of thumb is to clean the flue after every cord of wood burned, or whenever buildup reaches 1/8 inch thick.

Water Protection: The number one enemy of a masonry chimney is water. Ensure your chimney cap is secure and in good condition. Inspect the crown annually for cracks and have them sealed immediately to prevent water from penetrating the structure, which can lead to spalling of the flue tiles and deterioration of the masonry.

Be vigilant for signs of trouble:

If you notice clay tile pieces in your firebox, see visible cracks from the ground, experience persistent smoke spillage, or smell foul odors from the fireplace when not in use, cease using the fireplace immediately and call a professional. Repair options range from sealing minor cracks to a full relining with a stainless steel or cast-in-place system.

Yes, this is not only possible but is the standard, required procedure when installing a modern wood stove, fireplace insert, or certain types of gas appliances into an existing masonry chimney. The original 13×13 flue is too large for these efficient appliances, which would lead to poor draft and excessive creosote. The process involves installing a correctly sized, insulated stainless steel liner (typically 6″ for a wood stove) inside the clay flue. The clay tile then acts as a protective chase, and the insulation around the new liner is critical for maintaining high flue gas temperatures, ensuring safety and peak performance.

You need a cap designed to fit the actual outside dimensions of the tile, which are closer to 12.5″ x 12.5″. Do not buy a cap labeled simply “13×13” without measuring first. Common options include:

The only certain method is a Level 2 professional inspection, where a certified chimney sweep uses a specialized camera to view the entire length of the flue interior. However, there are several warning signs a homeowner can look for:

Absolutely not. Even a hairline crack that penetrates the tile wall is a serious hazard. It provides a pathway for intense heat and embers to reach the adjacent combustible woodwork of your home, potentially causing a fire inside the walls. It also allows deadly carbon monoxide to leak into your home. Any crack, no matter how small it appears, renders the chimney unsafe for use until it has been professionally evaluated and repaired or relined.

The National Fire Protection Association (NFPA) recommends an annual inspection for all chimneys, regardless of how often they are used. An unused chimney can still be damaged by weather, animals, or seismic events. Cleaning frequency depends on use. Heavy wood burners might need cleaning multiple times per season, while an occasional user might only need cleaning every few years. The annual inspection will determine if cleaning is necessary.

It depends on the extent and type of damage. Minor, isolated cracks might be repairable with specialized refractory patching compounds, but this is often a temporary fix. If the liner has extensive cracking, multiple gaps in the mortar joints, or is spalling (flaking surfaces), the only safe and permanent solution is to reline the chimney. The most common methods are installing a stainless steel liner or a cast-in-place liner.

Spalling is the process where the surface of the clay tile flakes or peels away. It is almost always caused by moisture penetrating the tile and then freezing, which forces the surface layers to pop off. Spalling is very dangerous because it weakens the structural integrity of the tile and creates a rough, pitted interior surface. This rough surface dramatically increases friction, hinders draft, and provides an ideal texture for flammable creosote to accumulate rapidly.

The 13×13 clay flue tile is more than just a ceramic tube; it is the foundational safety component at the core of countless residential chimney systems. For over a century, it has provided a reliable, code-compliant solution, combining immense heat resistance, structural integrity, and longevity when integrated into a properly constructed masonry chimney.

A well-built chimney system with a 13×13 clay flue liner creates a seamless, fire-resistant channel that performs two non-negotiable jobs: it safely vents toxic gases and intense heat out of your home, and it protects the surrounding structure from the constant threat of fire and heat damage.

Despite its inherent durability, a clay liner is not invincible. Its integrity is constantly challenged by powerful forces:

This is why the concept of “set it and forget it” does not apply to chimneys. Regular professional inspections are not an upsell; they are a critical safety measure to catch small, repairable issues before they evolve into major structural failures or create a life-threatening hazard like a house fire or carbon monoxide poisoning.

In today’s homes, the role of the 13×13 clay flue is evolving. While still the standard for new traditional fireplaces, it often serves a new purpose in existing homes. Many now function as a robust, protective chase for modern, high-performance lining systems. When a new wood insert or gas furnace is installed, the original clay flue provides the structural housing and the required clearance to combustibles for a new, perfectly sized stainless steel liner. This hybrid approach combines the time-tested strength of masonry with the efficiency and safety of modern venting technology.

The complexity of chimney physics, building codes, and material science makes professional expertise indispensable. A certified chimney professional can:

At Smithrock Roofing, we provide comprehensive chimney services for homeowners in Winston-Salem, Greensboro, and the surrounding communities. Our team of trained experts understands that a chimney is a complete system where every component must work in harmony. Whether you are building a new fireplace, upgrading an existing appliance, or seeking essential maintenance, we prioritize the safety, performance, and durability of your home.

Learn more about our services: professional chimney services.

Your 13×13 clay flue tile is a critical investment in your home’s safety and comfort. Understanding its function, respecting its vulnerabilities, and committing to its maintenance ensures it will serve you reliably and safely for years to come.

Smithrock Roofing © Copyright 2025 • All Rights Reserved • Privacy Policy • Maintained by Mongoose Digital Marketing