Understanding What You’ll Really Pay for a New Chimney Liner

Chimney liner installation cost is a primary concern for homeowners seeking to improve fireplace safety and efficiency. If a recent chimney inspection has revealed damage, or you’re noticing troubling signs like drafting issues, excessive smoke in your home, or debris in your firebox, a new liner is often the necessary solution. Homeowners may also need a new liner when upgrading an old fireplace or installing a new appliance, like a wood stove or gas insert, which requires a specific flue size for optimal performance.

This isn’t just a cosmetic upgrade; a chimney liner is a critical safety component of your home’s venting system. It serves as a barrier, protecting your home’s combustible structure (wood framing, walls, and insulation) from the intense heat of a fire, which can exceed 1,100°F. It also prevents corrosive, acidic gases from eating away at your chimney’s masonry from the inside out. Most importantly, a sound liner ensures that smoke and deadly, odorless carbon monoxide are channeled safely up and out of your home, preventing them from leaking into your living spaces through cracks or porous mortar joints. Without a functional liner, you face a significantly increased risk of devastating house fires and exposure to toxic gases.

The final price of your installation is not a single number but a sum of several parts, including the liner material, chimney dimensions and overall condition, and the complexity of the installation. This comprehensive guide will break down every element that influences your total cost, from material choices and labor rates to necessary repairs and permits, helping you make an informed and confident decision to protect your home and family.

Understanding Chimney Liners and Your Options

Before diving into the chimney liner installation cost, it’s crucial to understand what a liner does, the different types available, and which is best suited for your specific needs. The material you choose will be the biggest factor in your budget and the long-term performance of your chimney system.

What is a Chimney Liner and Why is it Essential?

A chimney liner, or flue liner, is a conduit installed inside your masonry chimney that contains the byproducts of combustion (heat, smoke, and gases) and directs them safely to the outside atmosphere. This seemingly simple component performs several critical safety functions that are non-negotiable for a modern chimney:

- Fire Prevention: A liner contains the extreme heat generated by your fireplace or appliance, preventing it from transferring to combustible materials like wood framing, drywall, and insulation within your home’s walls and attic. This is its most important function.

- Carbon Monoxide Safety: It creates a sealed, continuous, and correctly sized passage for this odorless, deadly gas to exit your home. Without a liner, CO can easily leak into living spaces through even minor cracks or porous mortar in an old chimney.

- Masonry Protection: The gases produced by burning fuel are highly acidic and corrosive. A liner shields your chimney’s bricks and mortar from this chemical attack, which would otherwise cause rapid deterioration, crumbling mortar (spalling), and eventual structural failure. It dramatically extends the life of your chimney structure.

- Improved Efficiency: A properly sized, smooth-walled liner improves the chimney’s draft. A strong, consistent draft helps your fireplace or appliance burn fuel more completely and efficiently, reduces smoke spillage into your room, and minimizes the buildup of flammable creosote.

Due to these undeniable safety benefits, building codes, including the NFPA 211 standard, now mandate liners for all new constructions and most new appliance installations. The Chimney Safety Institute of America (CSIA) considers a properly installed and maintained liner a fundamental safety requirement, not an optional upgrade.

Clay Tile Liners

Common in masonry chimneys built over the last century, clay tiles are a traditional and affordable option when installed during the initial construction of the chimney.

- Pros: Very low material cost, extremely long lifespan if they remain intact.

- Cons: They are brittle and highly susceptible to cracking from thermal shock (rapid temperature changes, such as during a chimney fire) or even minor house settling. Repairing cracked tiles is difficult and expensive, often requiring the chimney to be partially demolished and rebuilt. They are not suitable for relining an existing chimney.

- Best For: New, straight masonry chimney constructions only.

- Lifespan: Up to 50 years if properly installed and never subjected to a chimney fire or other stress.

Stainless Steel Liners

Stainless steel is the most popular and versatile modern choice for relining existing chimneys. Its flexibility and durability make it the go-to solution for most relining projects.

- Pros: Excellent durability, high heat tolerance, and superior corrosion resistance. They are available in flexible tubing (for chimneys with bends or offsets) and rigid sections (for straight flues), making them adaptable to nearly any chimney configuration. They are suitable for all fuel types (wood, gas, oil).

- Cons: Higher material cost compared to clay or aluminum. Quality varies, so it’s crucial to use the correct alloy for your application.

- Alloy Types: There are two common grades: 304 Stainless Steel is a durable choice for wood-burning fireplaces and gas appliances. 316Ti Stainless Steel contains titanium and molybdenum, offering superior corrosion resistance, and is required for burning coal or oil and recommended for high-efficiency gas appliances or any wood-burning application for maximum longevity.

- Best For: Relining existing chimneys, especially those with damage, offsets, or that were previously unlined. They are the standard choice for connecting new, high-efficiency wood stoves and inserts.

- Lifespan: 15 to 25 years, though many high-quality, professionally installed 316Ti liners come with a lifetime warranty.

For more information on keeping your chimney system in top condition, explore our comprehensive Chimney Services.

Aluminum Liners

Aluminum is a lightweight, budget-friendly metal liner, but its use is extremely limited due to its low heat tolerance.

- Pros: Lowest material cost among metal liners, lightweight, and relatively easy to install.

- Cons: Short lifespan and very restricted use. They cannot handle the high temperatures of wood or coal-burning appliances and will melt, creating a severe fire hazard. They are also less durable and more prone to corrosion than stainless steel.

- Best For: Venting certain low-to-medium-efficiency gas furnaces and water heaters (typically Category I appliances) only. They are never appropriate for fireplaces or wood stoves.

- Lifespan: 5 to 15 years.

Cast-in-Place Liners

This method involves creating a new, seamless, and permanent liner inside the chimney using a specialized cement-like material.

- Pros: Extremely durable and smooth, which improves draft. It adds significant structural strength to deteriorating or unlined chimneys, essentially creating a new, solid flue within the old structure. It is suitable for all fuel types and can be formed to fit any chimney shape or size. It is considered a permanent solution.

- Cons: This is the highest-cost option due to the specialized materials, equipment (inflatable forms), and labor-intensive professional installation process.

- Best For: Historic restorations or for severely damaged, crumbling, or unlined masonry chimneys that require structural reinforcement in addition to a new liner.

- Lifespan: 50+ years; often considered a permanent chimney restoration.

Key Factors That Influence Chimney Liner Installation Cost

Your final chimney liner installation cost is determined by a combination of factors unique to your home and chimney. Understanding these variables will help you interpret a contractor’s estimate and budget accordingly. A typical professional installation of a stainless steel liner for a single-story home can range from $2,500 to $7,000, but this can vary significantly.

The Impact of Liner Material and Type on Your Budget

The material you choose is the single largest driver of cost. Here’s a breakdown of material costs per foot, not including labor:

- Aluminum: The most budget-friendly at $10 – $25 per foot, but only for specific low-heat gas appliances.

- Clay Tile: Low material cost ($10 – $20 per tile section), but these are only used in new construction. Relining with clay tile is not feasible.

- Stainless Steel: A mid-to-high range investment offering the best value. Costs vary by grade and type: $20 – $70 per foot for flexible 304/316Ti liners, and $50 – $100+ per foot for pre-insulated or rigid double-wall liners.

- Cast-in-Place: The most expensive option, typically priced as a complete project rather than per foot, but can equate to $100 – $250 per foot, with total project costs often starting at $5,000 to $10,000 or more.

Double-wall insulated stainless steel liners cost more than single-wall versions but are highly recommended (and often required by code) for wood-burning applications in wood-frame construction. They improve safety by keeping the outer wall of the liner cooler and boost appliance efficiency by keeping flue gases hotter, justifying the higher initial investment.

Chimney Size, Shape, and Existing Condition

Your chimney’s physical state plays a major role in the project’s scope and cost.

- Height and Diameter: Taller and wider chimneys require more material and more labor, directly increasing the cost. A 35-foot, two-story chimney can cost nearly double that of a 15-foot, single-story chimney.

- Flue Shape: Most liners are round for optimal draft. Installing a round liner in a traditional square or rectangular flue requires adding insulation (blankets or poured mix) to fill the void. This is crucial for safety and performance and adds to the material and labor cost.

- Offsets and Bends: Chimneys that are not perfectly straight require a flexible liner and significantly more labor to navigate the turns. This increases installation complexity and cost.

- Pre-existing Damage: Before a new liner can be installed, any structural issues must be addressed. This can include tuckpointing deteriorated mortar joints, rebuilding parts of the chimney stack, or repairing a cracked chimney crown. These are separate costs from the liner installation itself but are essential for the safety and longevity of the entire system. For more about structural maintenance, visit our Roof Repair Services page.

Labor, Accessibility, and Installation Complexity

Labor typically accounts for $1,000 to $3,000+ of the total cost and is influenced by several factors.

- Regional Rates: Labor costs vary by location. We provide competitive, transparent pricing for homeowners throughout the Piedmont Triad.

- Roof Accessibility: Steeply pitched roofs, slate or tile roofs, and very tall chimneys are more difficult and dangerous to work on. They require extra safety equipment like harnesses, roof jacks, or even scaffolding, which increases labor time and cost.

- Number of Appliances: Venting multiple appliances (e.g., a furnace and a water heater) into one chimney requires more complex connections, fittings, and sealing, adding to the labor and material costs.

- Old Liner Removal: Removing an old, damaged liner takes time and effort. Breaking out old clay tiles is particularly labor-intensive and messy, potentially adding $500 to $2,500 or more to the total labor cost depending on the chimney’s height and the extent of the damage.

Deconstructing the Full Price: Additional Costs to Consider

Beyond the liner and base labor, several other essential services and components contribute to the final chimney liner installation cost. Budgeting for these items upfront ensures a complete, safe, and code-compliant project without surprise expenses.

Initial Inspection, Cleaning, and Permits

Before any installation work begins, these preparatory steps are crucial and have associated costs:

- Professional Inspection: A Level 2 inspection, as defined by the NFPA, is required before relining a chimney. This involves a visual check of all accessible parts of the chimney and a video camera scan of the flue’s interior to assess the condition and look for cracks, blockages, or other damage. This ensures the chimney is structurally sound enough for relining. Cost: $200 – $600.

- Thorough Cleaning: The chimney must be professionally swept to remove flammable creosote, soot, and other debris. A clean surface is essential for a proper inspection and to ensure the new liner fits correctly without being damaged during installation. This is a critical fire safety measure. Cost: $150 – $350.

- Building Permits: Many municipalities, including those in the Winston-Salem area, require a permit for chimney liner installation. This ensures the work is documented and inspected to meet local safety codes. Your contractor should handle the permitting process. Cost: $50 – $250.

The Role of Insulation in Your Chimney Liner Installation Cost

Insulating your new chimney liner is highly recommended for stainless steel liners in wood-burning systems and is often required by code. While it adds to the initial cost, the safety and performance benefits are significant:

- Improved Safety: Insulation provides a critical zero-clearance rating, meaning it reduces the liner’s exterior temperature sufficiently to be safely in contact with wood framing. This drastically reduces fire risk.

- Reduced Creosote: It keeps flue gases hotter all the way up the chimney. Hotter gases have a stronger draft and are less likely to cool and form condensation, which is the primary ingredient in flammable creosote buildup.

- Improved Performance: Better draft means your appliance starts easier, burns more efficiently, and is less likely to spill smoke into the room.

Insulation typically comes in two forms: insulating blankets, which are wrapped around flexible liners (adding $15 – $30 per foot), or a poured vermiculite/perlite mix, which fills the space around a rigid liner (adding $20 – $40 per foot).

Necessary Chimney and Roof Repairs

Often, a pre-lining inspection reveals other issues that must be addressed to ensure the entire chimney system is sound and watertight.

Common associated repairs and their typical costs include:

- Chimney Crown Repair/Rebuild: The concrete slab at the top of the chimney must be free of cracks to prevent water from seeping in and destroying the masonry. A simple seal might cost $200 – $500, while a full rebuild can cost $1,000 – $3,000.

- Tuckpointing: Replacing old, crumbling mortar between bricks is vital for the chimney’s structural stability. Cost: $25 – $50 per square foot.

- Flashing Repair/Replacement: The metal seal where the chimney meets the roof must be watertight to prevent leaks into your attic and home. Cost: $300 – $1,000. Learn more in our guide on Roof Repair vs Replacement.

- Chimney Cap Installation: A new cap is essential for keeping rain, animals, and debris out of your new liner. A quality stainless steel cap costs $300 – $700 installed.

DIY vs. Professional Installation: A Cost and Safety Analysis

When facing a multi-thousand-dollar chimney liner installation cost, the idea of a DIY project can be tempting. DIY liner kits are readily available online for a fraction of the professional price. However, this is one home improvement job where the risks of going it alone far outweigh any potential savings, and a mistake can have catastrophic consequences.

The DIY Chimney Liner Installation Cost and Risks

While a DIY liner kit might cost only $500 to $1,500, this price doesn’t account for necessary tools (ladders, scaffolding, safety harnesses, cutting tools), additional materials (insulation, high-temperature sealant, top plate, cap), and the significant risks involved.

Key risks of a DIY installation include:

- Incorrect Sizing: Professionals use specific calculations based on NFPA 211 standards, appliance specifications, and chimney height to determine the correct liner diameter. An improperly sized liner leads to poor draft, smoke spillage, excessive creosote buildup, and dangerous carbon monoxide accumulation.

- Improper Sealing and Connections: Every connection point—from the appliance to the liner and the liner to the top plate—must be perfectly sealed with the correct high-temperature sealant. Even small gaps can leak deadly carbon monoxide into your home or allow moisture to enter and damage the chimney structure.

- Skipping or Improperly Installing Insulation: Many DIYers omit insulation to save money. This is a grave error that creates a serious fire hazard by allowing excess heat to transfer to combustible materials in your walls and attic. It also violates building codes for most installations.

- Personal Safety Hazards: Working on a roof is inherently dangerous. Professionals have the training and safety equipment to manage these risks. You also risk exposure to carcinogenic soot and creosote without proper personal protective equipment (PPE), including respirators and eye protection.

- Voided Warranties and Insurance Issues: Most liner manufacturers require certified professional installation for their product warranties to be valid. Furthermore, if a fire occurs due to an improper DIY installation, your homeowner’s insurance may deny the claim.

- Code Violations and Failed Inspections: Many jurisdictions prohibit DIY liner installation due to the high safety risks. An improper installation will fail the final building inspection and will likely need to be completely removed and redone by a professional, effectively doubling your cost.

Hiring a Professional: What Are You Paying For?

Hiring a certified chimney professional is an investment in safety, quality, and peace of mind. The higher cost covers much more than just labor; it ensures the job is done correctly and safely from start to finish.

- Expertise and Experience: Professionals have the training to properly size the liner, navigate complex installations, identify and address underlying structural issues, and ensure the entire system works together efficiently and safely.

- Code Compliance: They are experts in national (NFPA 211) and local building codes, guaranteeing your installation is 100% compliant and will pass any required inspections.

- Insurance and Liability: Reputable contractors carry general liability and workers’ compensation insurance. This protects you and your property from any financial liability in the rare event of an accident or damage during the installation.

- Professional-Grade Materials and Tools: Professionals use higher-quality materials (like 316Ti steel and premium insulation) and specialized equipment for a more durable, efficient, and precise installation than is possible with a basic DIY kit.

- Warranty and Peace of Mind: Professional installations typically come with warranties on both labor and materials. This protects your investment for years to come and gives you the confidence that your family is safe.

When hiring, look for technicians certified by the Chimney Safety Institute of America (CSIA) or the National Fireplace Institute (NFI). You can find a certified professional via the NFI to ensure you’re hiring a qualified expert.

Frequently Asked Questions about Chimney Liner Installation

Is a chimney liner required by law?

In most situations, yes. The National Fire Protection Association (NFPA) Standard 211, which is the national safety standard for chimneys and vents, is adopted as law by most local building codes. This standard mandates that chimneys venting solid-fuel and oil appliances must have a liner. Local codes in areas like Winston-Salem and Greensboro almost always require a properly installed liner when building a new chimney, installing a new appliance (like a wood stove or insert), or relining a chimney after a fire or when damage is found.

While some very old chimneys may be “grandfathered in” and not legally required to be relined if untouched, this does not mean they are safe. Safety organizations like the CSIA universally recommend that all chimneys venting combustion byproducts be lined. Furthermore, your homeowner’s insurance policy may require a lined chimney and could deny a claim for a fire if it’s determined that a faulty or absent liner was the cause.

Can my old chimney liner be repaired instead of replaced?

Repair is sometimes an option, but it depends entirely on the liner material and the extent of the damage. For a clay tile liner, minor, isolated cracks in an otherwise sound flue can sometimes be repaired using a specialized cast-in-place ceramic sealant system (like HeatShield®). This process coats the inside of the flue, sealing cracks and gaps. However, this is often a temporary fix if the chimney structure is shifting, and it cannot fix shattered or missing tiles. The cost of this repair can sometimes approach the cost of relining with stainless steel.

If the clay tiles are shattered, missing, or the damage is widespread, replacement is the only safe option. For stainless steel liners, small holes can sometimes be patched, but significant corrosion or seam separation warrants a full replacement. A professional Level 2 video inspection is the only way to accurately assess the damage and determine if a repair is a viable and safe long-term option.

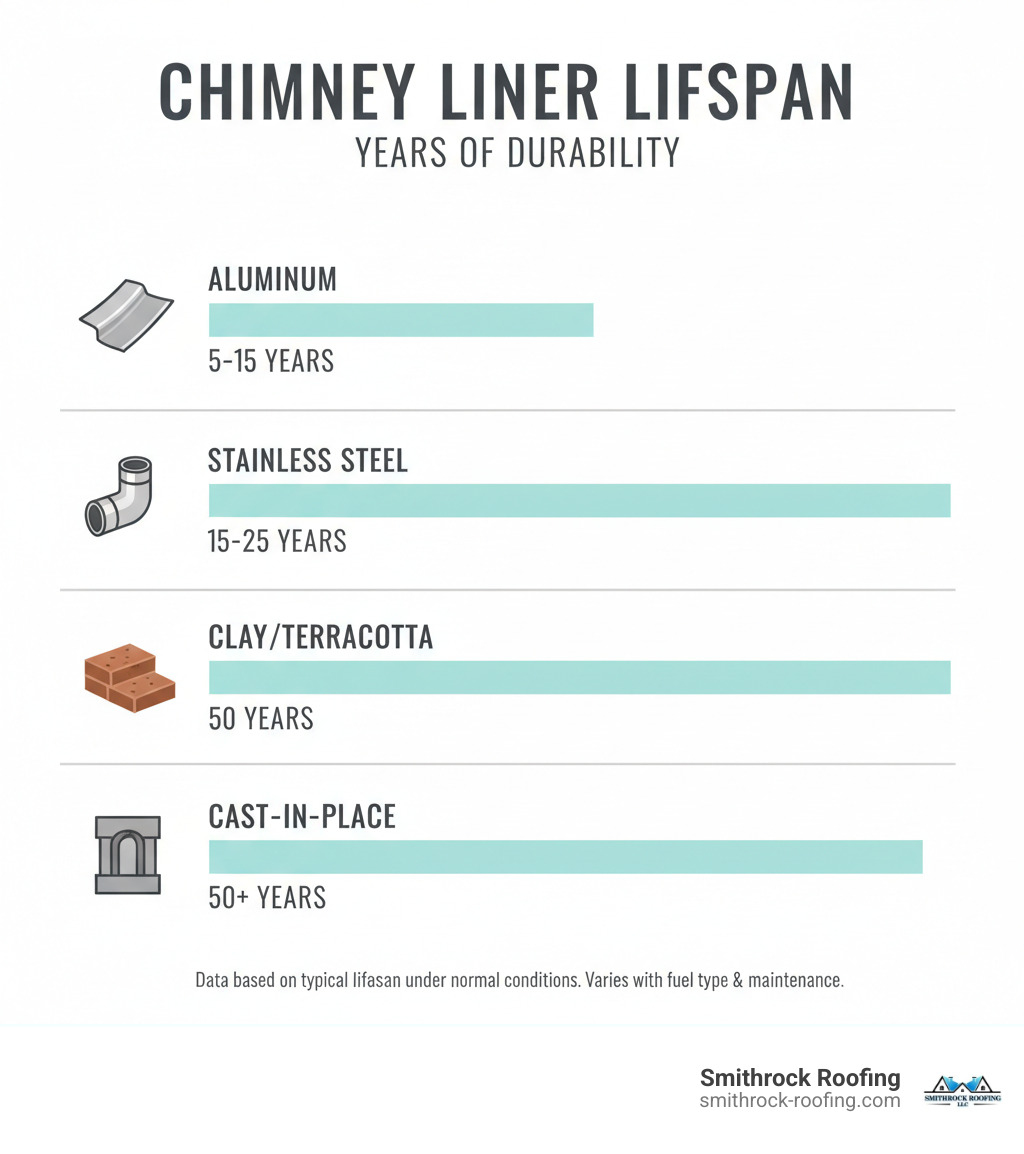

How long does a new chimney liner last?

The lifespan of your liner depends heavily on the material, installation quality, the type of fuel you burn, and your maintenance frequency. Regular annual inspections and cleanings are crucial to maximizing the life of any liner.

Here’s a comparison of typical lifespans:

| Liner Material | Typical Lifespan |

|---|

| Aluminum | 5-15 years |

| Stainless Steel | 15-25 years+ |

| Clay/Terracotta | 50 years |

| Cast-in-Place | 50+ years |

| Ceramic Sealants | 10-50 years |

High-quality materials, like 316Ti stainless steel, often come with lifetime warranties from the manufacturer when installed by a certified professional. Proper maintenance, including burning only seasoned hardwood and having the chimney swept annually, is the most important factor you can control to extend your liner’s service life.

What kind of maintenance does a new chimney liner require?

All chimney liners, regardless of material, require annual maintenance to remain safe and functional. This includes a professional inspection (at least a Level 1) and a cleaning (sweeping) to remove creosote and soot. For wood-burning systems, this is non-negotiable, as creosote is highly flammable. For gas or oil appliances, an annual inspection is still critical to check for blockages (like animal nests) and ensure connections are secure. This routine maintenance, typically costing $150 – $350, is the best way to protect your investment and ensure your liner lasts for its full expected lifespan.

Conclusion: A Smart Investment in Your Home’s Safety

Understanding the chimney liner installation cost requires looking beyond a single price tag and appreciating the project’s full scope. The total investment, which can range from $2,500 to over $10,000, is influenced by numerous factors, from the liner material you choose and your chimney’s height to the necessary prep work and structural repairs. While options range from budget-friendly aluminum for specific gas appliances to permanent cast-in-place solutions, a professionally installed, insulated stainless steel liner often provides the best balance of durability, safety, and long-term value for most homeowners.

A chimney liner is not an optional home improvement project; it is a critical safety feature that is essential for modern home safety. It actively protects your family from the dual threats of house fires and carbon monoxide poisoning, while also improving your heating appliance’s efficiency and preserving the structural integrity of your chimney for decades. The long-term value of a professionally installed, code-compliant liner far outweighs the initial expense by preventing catastrophic damage and avoiding far more costly structural repairs in the future.

Choosing professional installation is the only way to guarantee the job is done correctly, meets all NFPA 211 and local safety codes, and is backed by a valid warranty. An amateur installation risks not only your investment but the safety of your entire household. At Smithrock Roofing, our expert team serves Winston-Salem, King, High Point, and communities throughout the Piedmont Triad. We have the certified expertise to thoroughly assess your chimney, recommend the right solution for your budget and needs, and perform a flawless, safe installation.

For expert advice on your home’s exterior needs, from the roof to the chimney, explore our comprehensive chimney services. We are here to help you make an informed decision that protects your home and family for years to come.