A copper chimney cap is a critical consideration for homeowners seeking to protect their investment while enhancing their home’s exterior appeal. There’s a certain satisfaction in looking up at your home and seeing a well-crafted copper chimney cap gleaming against the sky. But that satisfaction comes from a premium option that often stands apart from standard chimney cap choices.

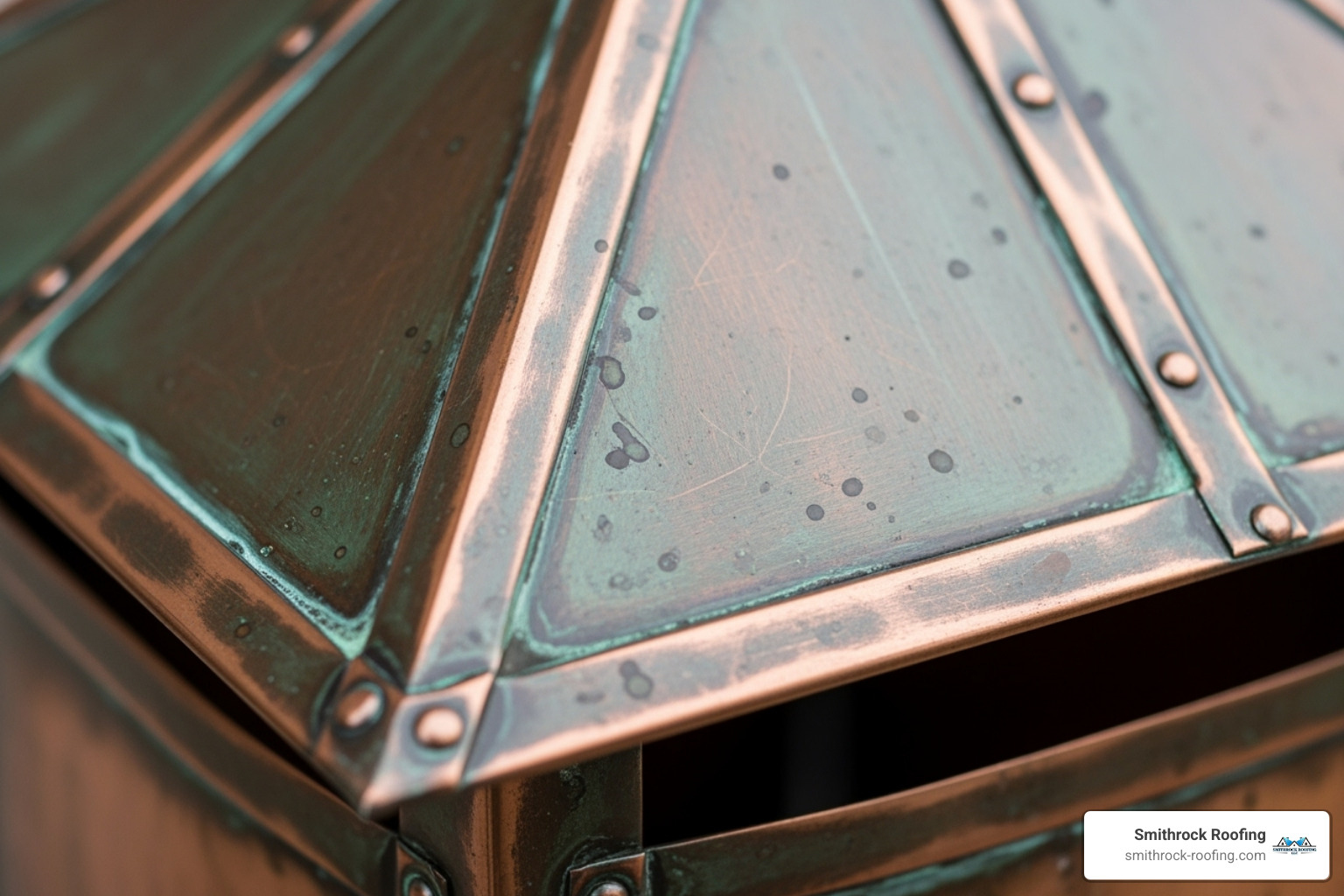

Why is copper considered a premium material? It’s a scarce, high-end metal that doesn’t rust, is often handcrafted by skilled artisans, and is built to last a lifetime. Unlike galvanized steel caps that might need replacement in 5-10 years, or aluminum caps that can dent and fade, copper improves with age. The natural patina that develops over time creates that distinctive green-blue finish you see on historic buildings—a sign of quality that actually increases your home’s curb appeal.

Research shows that copper is the most distinguished chimney cap metal, and for good reason. It offers superior weather resistance, prevents animal entry and water damage, and serves as both a functional necessity and an architectural statement. For homeowners concerned about energy efficiency and protecting their investment from harsh weather, understanding what makes a copper chimney cap a premium option helps you make an informed decision.

This guide breaks down every factor that influences a copper chimney cap project—from the gauge of the copper itself to the complexity of custom designs, from single-flue applications to elaborate multi-flue covers, and from material considerations to professional installation.

Easy copper chimney cap cost glossary:

When you start exploring what goes into a copper chimney cap project, you’ll find it’s not a simple, one-size-fits-all endeavor. The material itself is just the starting point—how much copper you need, how thick it is, and what design features you want all play starring roles in defining the final product.

Understanding these factors is about recognizing the value behind the investment. From the raw copper that forms the foundation to the artisan’s skilled hands that shape it into a functional work of art, each element contributes to a product that will protect your home for decades. Let’s break down exactly what influences the scope of these premium chimney caps.

The first thing to understand about copper is that it’s a premium material. Unlike galvanized steel or aluminum, copper is a genuinely scarce resource. The global copper market is entering an age of extremely large deficits, which means this valuable metal is only becoming more sought-after. This scarcity is a key reason it is considered the most distinguished chimney cap metal available.

The gauge thickness of the copper—essentially how thick the metal is—plays a huge role in performance. A 16 oz. copper standard refers to the weight of copper per square foot. A heavier gauge provides exceptional weather resistance and structural integrity, standing up better to harsh winds and heavy snow loads. This durability means your cap won’t dent or buckle the way thinner metals might.

High-purity copper also offers superior corrosion resistance. Unlike steel that rusts and deteriorates, copper develops a protective patina over time. This natural process shields the metal beneath, creating a self-protecting surface that can last a lifetime. That distinctive green-blue patina isn’t damage—it’s a sign of quality and graceful aging.

Basic geometry plays a significant role: bigger chimneys need bigger caps, which require more material. The chimney flue dimensions and chimney crown measurements are the starting points for any cap project, determining the necessary material quantity.

The complexity grows when comparing single-flue caps to multi-flue caps. A single-flue cap is a targeted solution for one chimney pipe. A multi-flue cap is engineered to cover several flue tiles or an entire chimney crown, requiring substantially more copper and more complex fabrication to ensure proper ventilation for each flue.

The overall cap height also factors in, as adequate space is needed between the flue tiles and the cap’s roof to ensure proper draft. Taller caps use more material and may require more intricate support structures, adding to the project’s complexity. The bottom line is simple: the material quantity needed directly correlates with your chimney’s size and configuration.

This is where copper chimney caps truly separate themselves. While prefabricated caps exist in standard sizes for quick installation, the real value of copper shines through in custom fabrication. This choice significantly influences the final design and character of the cap.

Custom fabrication opens up a world of architectural styles, whether you want a classic hip roof style, an neat French curve style, or something unique to your home. Chimney shrouds can be designed to cover the entire chimney crown, creating a seamless look that transforms your chimney into an architectural focal point.

The artistry available in custom work is remarkable, with options like intricate scrollwork or decorative finials. These details require skilled craftsmanship and more labor hours. Many high-quality copper caps are handmade in the USA by experienced metal fabricators, ensuring superior quality and a precise fit that automated manufacturing cannot replicate. This level of custom work and expert artistry delivers a product that’s truly one-of-a-kind. For homeowners who view their chimney cap as an opportunity to improve curb appeal, custom copper fabrication is an investment in both function and beauty. At Smithrock Roofing, we work with skilled fabricators to bring your vision to life.

When homeowners first learn about the investment for a copper chimney cap, there can be a moment of surprise. Copper is a premium material, but choosing it is a strategic investment in your home’s future. The benefits it delivers in terms of durability, aesthetics, and property value far outweigh the initial outlay. A copper cap can pay for itself over time, not just in avoided replacement costs, but in the tangible value it adds to your home.

Let’s start with the most practical reason to choose copper: it outlasts everything else. A copper chimney cap is a lifetime material. A properly fabricated and installed copper cap can last 50 years or more—often for the entire life of your home.

Compare that to galvanized steel, which may show rust in as little as 5 years. The difference is that copper does not rust. Instead, it forms a protective patina layer that strengthens its resistance to the elements. Aluminum caps, while rust-proof, are much softer and can dent from hail or falling branches. Copper stands up to harsh weather—heavy rain, snow, and fierce winds—with best resilience.

This superior weather resistance is key to preventing chimney deterioration. By sealing the top of your chimney, a copper cap keeps moisture out. Water is the enemy of masonry, causing mortar to crumble and bricks to crack. A copper chimney cap is your first line of defense, protecting your entire chimney system for decades.

More info about our Chimneys services

Beyond its function, copper offers a genuine beauty that evolves. A new copper chimney cap has a bright copper finish that is stunning right away. But the real magic happens over the following months and years. Through natural oxidation, it develops a patina—that distinctive coloration seen on historic copper roofs.

The change is gradual, moving from bright copper to rich browns, then to deeper greens and blues. This verdigris patina is not damage; it’s a highly desired characteristic that gives each cap a unique character. This evolving appearance transforms a chimney cap into an architectural statement, adding sophistication and signaling quality. For homeowners thinking about resale value, a custom copper chimney cap is a high-end feature that potential buyers notice, contributing to increased property value.

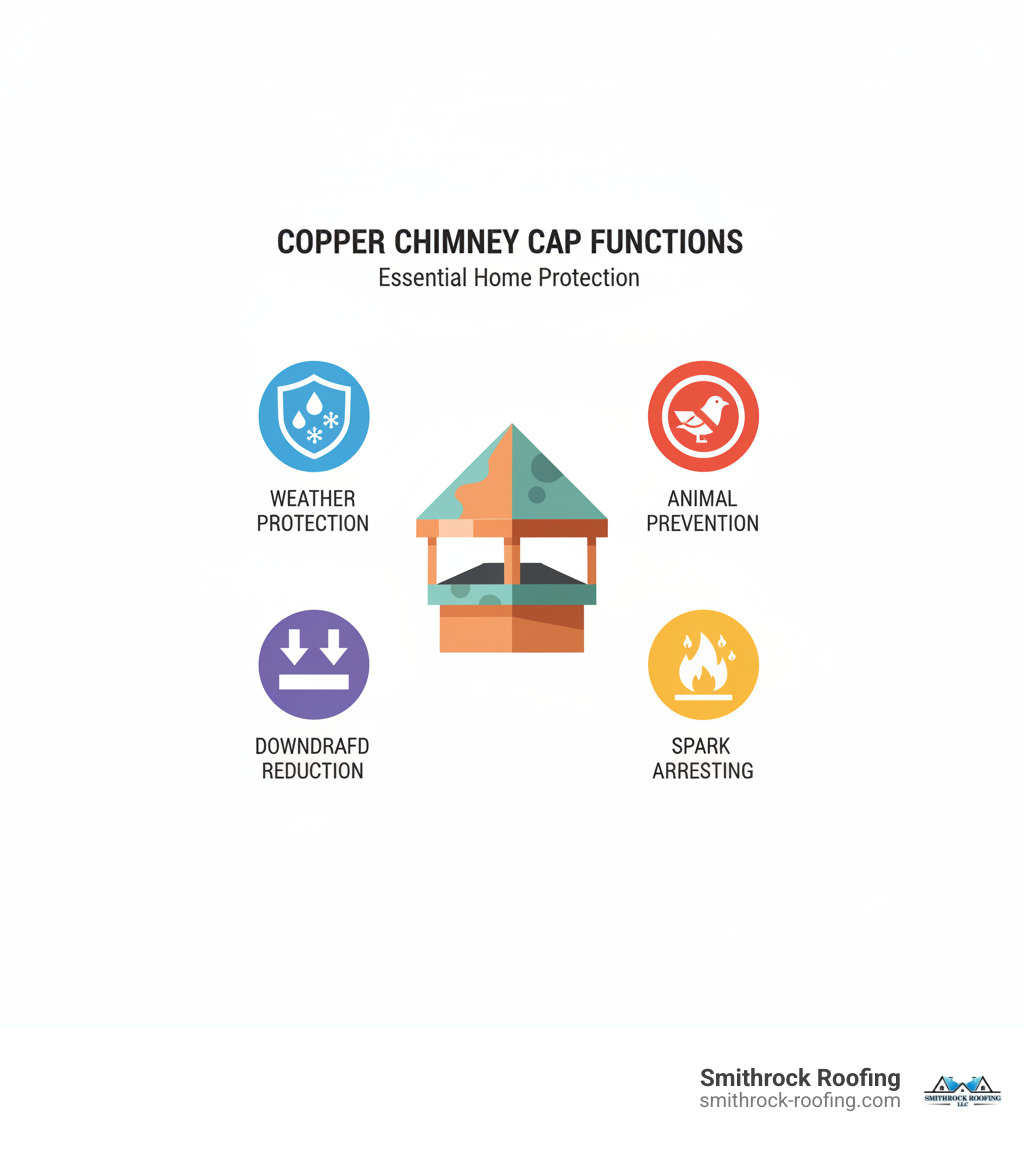

A chimney cap’s primary job is protecting your home. A well-designed copper cap provides multiple layers of defense more effectively than lesser materials.

Preventing water intrusion is job number one. An uncapped chimney allows rain and snow to pour in, leading to deteriorated mortar, rusted dampers, and corroded flue liners. A copper cap’s robust design sheds water away, keeping the interior dry.

Next is blocking animal entry. Birds, squirrels, and raccoons see chimneys as prime real estate, building nests that can cause dangerous blockages and fire hazards. The integrated mesh screening on copper caps keeps animals out while allowing smoke to exit.

Spark arresting is another critical safety function. A cap with proper screening acts as a spark arrestor, catching hot embers from a wood fire before they can land on your roof or in your gutters. This is a required safety feature in many areas.

Finally, a well-designed cap can improve chimney draft and prevent downdrafts. By influencing airflow, it ensures smoke is efficiently drawn out of your home, improving fireplace performance and indoor air quality. When you add up all these protective functions, the investment in a copper cap starts to look like an insurance policy for your home’s structure, safety, and comfort.

More info about our Roof Repair Services

When evaluating the total investment for a copper chimney cap, it’s important to look beyond the cap itself. The installation process, along with any preparatory work, represents a substantial portion of the overall project. Installing a custom copper cap is not a typical DIY job. It involves working at heights and requires specialized knowledge to ensure a proper fit and function. The quality of the installation directly affects how well your copper cap protects your home.

This section breaks down the expenses associated with getting your new copper cap safely and correctly installed, from skilled labor to the preparatory work that ensures your chimney is ready.

The labor involved in installing a copper chimney cap significantly influences the final project scope. This isn’t just about time on the roof; it encompasses the complexity and safety of the job.

The expertise of the installer matters tremendously. A professional roofer or a chimney sweep brings critical experience. At Smithrock Roofing, we prioritize comprehensive expertise, ensuring our team understands everything from safe roof access to optimal chimney performance.

Roof accessibility is a major factor. A chimney on a simple, low-pitched roof is far different from one atop a multi-story house with a steep roofline. Difficult access may require specialized equipment like scaffolding, which adds to the project’s complexity. The roof pitch complexity itself presents challenges, as steep roofs require more caution and time. Similarly, single-story versus multi-story homes present different levels of difficulty.

Sometimes, the job requires specialized equipment beyond standard ladders, such as roof jacks or mechanical lifts. The value of experienced professionals who understand rooftop safety and proper chimney cap installation cannot be overstated. A properly installed copper cap will serve your home for decades.

Before your new copper chimney cap can be installed, important preparatory work is often needed. These steps are crucial investments in ensuring your new cap performs optimally.

We always recommend starting with a thorough professional chimney inspection. This identifies any underlying issues that need addressing first.

Chimney crown repair is often critical. The crown is the concrete slab at the top of your chimney that sheds water. If it’s cracked or deteriorated, it needs repair. Installing a new cap on a faulty crown won’t provide the protection you need.

The flue liner condition also demands attention. A damaged liner is a safety hazard and should be repaired before cap installation. Any necessary masonry repairs, such as fixing loose bricks or deteriorated mortar joints, should also be completed to provide a stable base for the cap. Finally, building permits may be required to ensure work meets local safety codes. Addressing these items ensures your new copper cap is installed on a sound, healthy chimney, maximizing its protective benefits.

We understand the temptation to save on project costs by attempting a DIY installation. However, we strongly advise against it for several critical reasons.

The safety risks of DIY installation cannot be overstated. Working on a roof is dangerous, and falls are a leading cause of serious injuries for homeowners. Without proper safety gear and training, you’re taking an unnecessary risk.

Professional installers come with the specialized tools for safe access and secure attachment. Lacking the right tools can lead to an improper installation that compromises the cap’s effectiveness. Ensuring a proper seal is another area where professional expertise is invaluable. An amateur installation might leave gaps that lead to water damage or allow the cap to blow off in a storm.

Furthermore, many manufacturers’ warranties are contingent on professional installation. A DIY job could void your warranty, leaving you unprotected. The value in professional expertise goes beyond physical installation. Experienced pros understand chimney mechanics and drafting requirements, ensuring the cap is positioned to optimize performance. For safety, effectiveness, and peace of mind, we always recommend professional installation from experienced roofers or chimney specialists. The roofing contractors at Smithrock Roofing bring decades of combined experience to every installation.

When you’re considering the investment in a copper chimney cap, it’s not just about the upfront project. The real value comes from knowing where your cap is made, what quality standards it meets, and how little work it will need over its lifetime. These considerations help ensure your investment delivers decades of protection and beauty.

The source of your copper chimney cap matters. For exceptional quality, custom metal fabricators are the gold standard. These artisans specialize in copper, shaping it into functional and beautiful forms that off-the-shelf products cannot match.

Working with local roofing contractors like Smithrock Roofing offers another advantage. We have built relationships with trusted manufacturers, giving us access to quality products and the knowledge to recommend the right cap for your situation. We understand local weather patterns and architectural styles.

If you’re exploring online retailers, do your homework. Look carefully at product specifications, customer reviews, and warranty information. Vague guarantees can be a red flag.

Vetting installers is equally critical. Ask about their experience with copper caps, request references, and review portfolios of completed work. A skilled installer understands that a premium copper cap deserves a premium installation.

Not all copper chimney caps are created equal. The difference often comes down to craftsmanship and manufacturing standards.

UL Listed and OMNI Listed standards are recognized quality benchmarks. When a cap carries these certifications, it has been independently tested for safety and performance, signaling a manufacturer’s commitment to quality.

The designation Handmade in the USA also carries significant weight, reflecting a manufacturing approach that prioritizes craftsmanship. American artisans bring decades of experience to each cap, creating joints and seams that hold strong through years of weather.

Quality craftsmanship reveals itself in the details. Look for reinforced corners, smooth and complete welds, and securely attached mesh screens. These construction details determine whether your cap will last for decades. Weld quality alone can tell you volumes about a cap’s overall durability. Strong, clean welds create a monolithic structure that can withstand the elements.

One of the most pleasant surprises about copper chimney caps is how little they require after the initial investment. From a functional maintenance perspective, copper caps are wonderfully self-sufficient. You won’t be scraping rust or applying protective coatings. The primary task is keeping the mesh screen clear of debris, which can be checked during your annual chimney inspection.

The patina process is a key feature. The evolving color—from bright copper to deep greens and blues—is a natural chemical reaction that creates a protective layer. This is why copper has been used on historic buildings for centuries.

For those who prefer the shiny look, optional aesthetic cleaning is available with specialized solutions. Some also apply sealants to prevent patina, though these require periodic reapplication. Most owners, however, accept the natural aging process.

The beauty of minimal maintenance is clear when you consider the lifetime of the product. While the initial investment is significant, you avoid the recurring costs of rust treatments or premature replacements needed for other materials. Annual inspections are the best way to ensure your cap remains secure and functional, protecting your investment for decades to come.

We understand that investing in a copper chimney cap brings with it a few common questions. Let’s address some of the most frequent inquiries we receive to help you gain a clearer picture of this beautiful and functional chimney solution.

This is a common question with an excellent answer. A properly fabricated and installed copper chimney cap is considered a lifetime product. Unlike galvanized steel, which may rust in as little as 5 years, copper doesn’t rust at all. It is highly resistant to corrosion, meaning it can last for 50 years or more. In many cases, a quality copper cap will outlive the home itself. This exceptional longevity is a primary reason homeowners choose copper, as they are making a one-time investment rather than facing repeated replacements.

Yes, absolutely. A custom copper chimney cap can significantly increase your home’s curb appeal and resale value. From a potential buyer’s perspective, details signal quality and care. A gleaming copper cap—or one with a beautiful aged patina—immediately communicates an investment in premium materials. Real estate professionals often note that distinctive exterior features like copper caps contribute to what’s called “perceived value,” helping properties stand out and potentially leading to faster sales and better offers.

This is a fair question, as there is a notable difference between materials. The premium nature of a copper chimney cap compared to stainless steel comes down to several factors.

First, copper is a scarcer and more valuable raw material than steel. The global market dynamics for this commodity contribute to its standing as a premium metal.

Second, copper caps are often custom-fabricated by skilled artisans, involving more intensive labor than mass-produced steel caps. Many are handmade in the USA, with careful attention to detail. This artisan approach requires time and expertise.

Third, there’s the aesthetic factor. Copper offers a distinctive patina that develops over time, a natural aging process that creates a unique appearance many homeowners specifically seek. You’re not just investing in function; you’re investing in beauty that evolves. This combination of material value, skilled craftsmanship, and superior aesthetic appeal results in a premium product.

When you step back and look at the complete picture, a copper chimney cap represents far more than just another home improvement project. It’s a thoughtful, long-term investment in your home’s safety, efficiency, and visual appeal that continues to deliver value year after year.

We’ve walked through the factors that define a copper chimney cap project—from the inherent value of copper as a premium material to the quality of fabrication, from the size and complexity of your chimney to the custom designs that can create an architectural statement. We’ve also explored the importance of professional installation and the minimal ongoing maintenance these caps require.

While the initial investment for copper is significant, its longevity makes the value proposition clear. You’re investing in decades of worry-free protection against water damage, animal intrusion, and fire hazards, all while enhancing your home’s curb appeal with a material that becomes more beautiful with age.

The natural patina that develops on copper is a visible testament to quality craftsmanship that potential buyers recognize and appreciate. This isn’t just about protecting your chimney—it’s about making a statement about the care you’ve invested in your property.

At Smithrock Roofing, we understand that choosing the right chimney protection involves balancing long-term benefits with practical needs. Our team has the experience to guide you through every step, from selecting the perfect design to ensuring a safe, proper installation that maximizes the cap’s performance and lifespan.

If you’re ready to protect your home with a solution that combines superior functionality with timeless beauty, we’re here to help. Explore our comprehensive chimney services to get started, and let’s discuss how a custom copper chimney cap can improve your home for generations to come.

Smithrock Roofing © Copyright 2025 • All Rights Reserved • Privacy Policy • Maintained by Mongoose Digital Marketing