Why Roof Slab Leak Repair Demands Professional Expertise

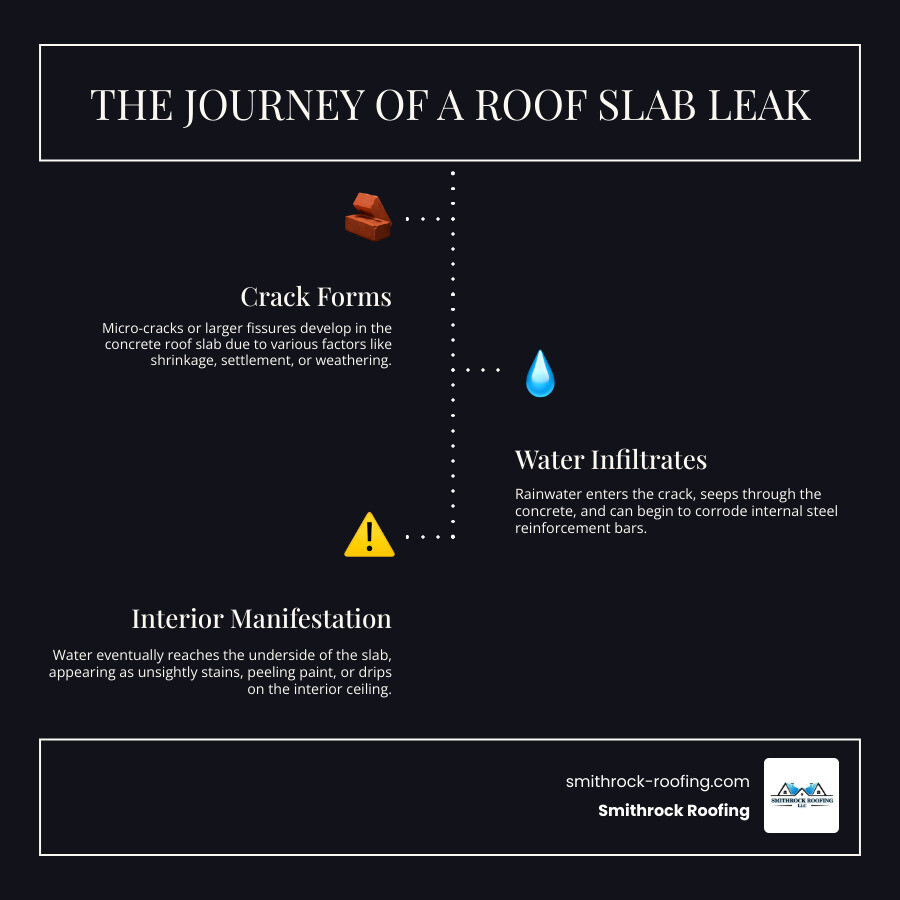

If you’re seeing ominous water stains on your ceiling or noticing cracks forming on your concrete roof, you’re likely facing a roof slab leak. This isn’t a minor inconvenience; it’s a direct threat to your property’s structural health. Roof slab leak repair is the highly specialized process of identifying, accessing, and permanently sealing leaks in concrete roof structures. Unlike fixing a few loose shingles, this process involves a deep understanding of concrete behavior, advanced waterproofing technologies, and structural engineering principles.

The stakes are incredibly high. Water infiltrating a concrete roof slab doesn’t just cause unsightly stains. Concrete is a porous material, and persistent moisture initiates a destructive chain reaction. It can corrode the internal steel reinforcement bars (rebar) that provide the slab with its tensile strength. As the rebar rusts, it expands, exerting immense pressure on the surrounding concrete. This leads to spalling—where chunks of concrete crack, break, and fall away—and delamination. Left unchecked, this corrosion compromises your home’s structural integrity, turning a simple leak into a potential safety hazard requiring costly structural repairs.

Most homeowners who attempt DIY fixes with caulk or patch kits find the leak returns, often worse than before. This is because surface patches fail to address the root cause, which could be anything from structural movement to a systemic failure of the original waterproofing. Professional roofers, however, are equipped with specialized tools and proven methodologies to diagnose and permanently resolve these complex issues.

Key Methods Professionals Use:

- Epoxy or Polyurethane Injection: For deep structural cracks, professionals inject high-strength resins under pressure. This not only seals the leak but also rebonds the concrete, restoring its structural integrity from the inside out.

- Liquid-Applied Waterproofing Membranes: These advanced elastomeric coatings are applied as a liquid to create a seamless, flexible, and monolithic barrier across the entire roof surface, effectively shrink-wrapping it against moisture.

- Torch-On or Self-Adhered Sheet Membranes: For maximum durability, multi-ply sheet systems (like modified bitumen or EPDM rubber) are installed. These create a robust, puncture-resistant shield designed for long-term performance.

- Hydraulic Cement & Crystalline Waterproofing: For actively leaking cracks and voids, hydraulic cement is used to plug the flow of water instantly. Crystalline admixtures can also be applied, which penetrate the concrete’s pores and form insoluble crystals to block water pathways permanently.

- Professional Leak Detection: Before any repair, experts use non-invasive tools like thermal imaging cameras and electronic moisture meters to precisely map the extent of water intrusion and pinpoint the exact source, eliminating guesswork.

When to Call a Professional Immediately:

- Water stains appearing on ceilings or high on walls below concrete slabs

- Visible cracks, spalling, or deterioration on the roof surface

- Persistent musty odors or visible mold and mildew growth indoors

- Ponding or standing water on flat concrete roofs more than 48 hours after rain

This guide will walk you through exactly what professionals do to diagnose and repair a roof slab leak, empowering you to make informed decisions to protect your most valuable asset.

Identifying the Source: Is It Your Roof Slab or Something Else?

When water damage appears inside your home, the first and most critical step is determining its origin. A wrong diagnosis leads to wasted time, unnecessary expense, and continued deterioration of your property. Is the culprit your concrete roof slab, or could it be a hidden plumbing issue? Let’s explore the diagnostic process used to tell the difference.

Signs of a Roof Slab Leak

A roof slab leak leaves a distinct trail of evidence. The most obvious clue is water stains on your ceiling. These often begin as faint, discolored patches and grow into well-defined yellowish or brownish rings that expand and darken after it rains. Other common indicators include:

- Paint and Texture Damage: Peeling, bubbling, or blistering paint on ceilings and upper walls is a classic sign that moisture is trapped behind the surface.

- Musty Odors: A persistent, earthy smell, especially in upper-floor rooms or closets, suggests hidden moisture that is fostering mold and mildew growth long before it becomes visible.

- Efflorescence: On unpainted concrete or masonry surfaces, you might see a white, chalky powder. This is efflorescence—salt deposits left behind as water seeps through the concrete and evaporates, indicating a chronic moisture problem.

- Audible Dripping: In quiet moments, you may hear the faint sound of dripping inside a ceiling or wall cavity, a definitive sign of an active leak.

If you can safely access your roof, a visual inspection can be revealing. Look for visible cracks, from hairline fissures to larger, more obvious fractures. Check for ponding water—areas where water collects and stands for more than 48 hours after rainfall. These low spots put immense, constant pressure on the waterproofing system. Also, look for moss, algae, or vegetation growth, as these only grow where moisture is consistently present.

Differentiating from Plumbing Leaks

Plumbing leaks can sometimes mimic roof leaks, but several key differences help distinguish them. A methodical approach can save you from barking up the wrong tree.

- The Water Meter Test: This is the most reliable way to check for a pressurized plumbing leak. First, ensure all faucets, toilets, and water-using appliances are turned off. Then, locate your water meter and watch the leak indicator (often a small triangle or dial). If it’s moving, you have a leak somewhere in your plumbing system. If it’s stationary, the leak is likely coming from an external source, such as the roof.

- Location and Appearance: Plumbing supply lines are often routed through walls or ceilings. A leak from a supply line is typically constant and may appear as a persistent drip or a rapidly growing wet spot. A leak from a drain line will only appear when the fixture above it (like a shower or toilet) is used. In contrast, roof leaks are almost always correlated with weather events like rain or snowmelt.

- Water Temperature: If you have a slab-on-grade foundation, a warm spot on the floor is a tell-tale sign of a hot water line leak. For upper-level leaks, carefully touch the damp area. If it feels warm, a hot water pipe is the likely suspect. Roof leaks will be at ambient temperature.

Professional Leak Detection: The Science of Finding Water

Sometimes the source isn’t obvious, as water can travel horizontally along ceiling joists or within the concrete slab itself, appearing far from its entry point. This is where professional leak detection becomes indispensable.

Professionals use advanced, non-destructive tools to pinpoint leaks with surgical precision:

- Moisture Meters: These handheld devices use either pins to measure electrical resistance or a non-invasive radio frequency to detect moisture content in building materials like drywall, wood, and concrete. By taking readings across an affected area, a technician can trace the path of moisture back to its highest concentration, leading them to the source.

- Thermal Imaging (Infrared) Cameras: These powerful cameras detect minute differences in surface temperature. Wet materials cool as moisture evaporates, making them appear colder than surrounding dry materials. An infrared camera can instantly reveal the full extent of hidden water intrusion within ceilings, walls, and the roof slab itself, creating a “moisture map” that is invisible to the naked eye.

- Acoustic Leak Detectors: For pressurized pipe leaks, these systems use highly sensitive microphones and amplifiers to \”listen\” for the distinct hissing or rushing sound water makes as it escapes a pipe. This is particularly useful for finding plumbing leaks hidden within concrete slabs or walls.

- Tracer Gas Systems: In especially difficult cases, a non-toxic, inert gas (like a hydrogen/nitrogen mix) is injected into a pipe system. The gas, being lighter than air, escapes through the leak and rises to the surface, where a sensitive gas \”sniffer\” detects its presence, pinpointing the exact location of the breach.

Special Considerations for Underground Homes

Underground or earth-sheltered homes present unique challenges for roof slab leak repair. The roof slab is buried under layers of soil, insulation, and drainage material, making direct access impossible. If interior patches fail repeatedly, the problem almost certainly originates from a failure in the exterior waterproofing membrane. Hydrostatic pressure from saturated soil exerts constant force on the structure. Pay close attention to leaks at cold joints (where the walls meet the roof slab) and be aware of potential root intrusion from nearby trees, which can aggressively penetrate waterproofing membranes and concrete over time.

No matter your home’s design, a professional assessment is the smartest and most cost-effective first step. At Smithrock Roofing, we offer thorough Roof Inspection services to accurately diagnose your leak’s source and recommend the right, permanent solution. Guesswork has no place when protecting your home.

Common Culprits: What Causes Concrete Roof Slabs to Leak?

Understanding why a robust material like concrete leaks is the first step toward an effective, long-lasting repair. Concrete roof slabs, especially flat or low-slope designs, are subjected to a unique combination of structural stress, relentless weather, and design challenges. Here are the most common culprits behind a leaking concrete roof.

Structural Cracks and Movement

While concrete is strong in compression, it’s weak in tension, making it prone to cracking. These cracks create direct highways for water to penetrate the slab.

- Shrinkage Cracks: As new concrete cures and dries, it shrinks. This process can create a network of fine, random cracks (crazing) or larger, more defined cracks if not properly managed with control joints. These are often the first entry points for water.

- Structural Settlement: All buildings settle over time. If this settlement is uneven, it creates differential stress across the roof slab, leading to significant structural cracks that can widen over time.

- Thermal Expansion and Contraction: Concrete expands when heated and contracts when cooled. This constant daily and seasonal movement puts immense stress on the slab. Without properly designed and maintained expansion joints to accommodate this movement, the concrete will relieve the stress by cracking.

Weathering and Material Deterioration

No material is immune to the effects of weather. Constant exposure to the elements slowly but surely breaks down the concrete itself and its protective layers.

- Freeze-Thaw Cycles: This is one of concrete’s greatest enemies. Water seeps into microscopic pores and cracks, then freezes. As water turns to ice, it expands by about 9%, acting like a powerful wedge that widens the crack. This cycle repeats, progressively breaking the concrete apart in a process called spalling.

- UV Degradation and Weathering: The sun’s ultraviolet rays break down the chemical bonds in protective coatings and sealants, making them brittle and ineffective. Over time, UV radiation and acid rain can also erode the cement paste on the concrete’s surface, exposing the aggregate and increasing its porosity.

- Carbonation: Atmospheric carbon dioxide reacts with the calcium hydroxide in concrete, forming calcium carbonate. This chemical process slowly reduces the concrete’s natural alkalinity (pH). This is critical because the high pH of healthy concrete forms a passive, protective layer around the steel rebar. Once carbonation lowers the pH, this protective layer is destroyed, leaving the rebar vulnerable to rust and corrosion when moisture is present.

Failed Waterproofing Membrane

Most concrete roofs are not inherently waterproof; they rely on a separate waterproofing membrane for protection. When this critical layer fails, roof slab leak repair becomes urgent. Common failure modes include:

- Punctures, Tears, and Abrasion: Foot traffic during maintenance, dropped tools, falling branches, or even hail can puncture or tear the membrane, creating an immediate leak point.

- Blistering and Delamination: If moisture gets trapped between the concrete slab and the membrane, solar heat can cause it to vaporize and expand, creating large blisters. These blisters can eventually rupture, and the delamination allows water to travel freely underneath the membrane.

- Seam Failure: For sheet-based membranes (like torch-on or EPDM), the seams between rolls are the weakest link. Improper installation, aging adhesives, or structural movement can cause seams to open up.

- Material Aging: All waterproofing materials have a finite lifespan. Over time, exposure to UV rays and temperature fluctuations causes materials like asphalt and some plastics to become brittle, shrink, and crack, losing their flexibility and adhesive properties.

Poor Drainage: The Root of Most Evil

Poor drainage is arguably the single biggest contributor to flat concrete roof failures. Water that doesn’t drain becomes a relentless enemy.

- Ponding Water: A \”flat\” roof should never be perfectly flat. Building codes mandate a minimum slope (typically 1/4\” per foot) to direct water toward drains. When this slope is inadequate or the structure sags, water collects in low spots. This standing water, known as ponding, puts constant hydrostatic pressure on the waterproofing system, accelerating its deterioration and exploiting any tiny flaw. According to government research on flat roof deterioration, ponding water can cut a roof’s lifespan in half.

- Clogged Drains and Scuppers: Drains, scuppers (outlets through parapet walls), and gutters can easily become clogged with leaves, dirt, and other debris. A single clogged drain can cause massive amounts of water to back up, turning the roof into a shallow swimming pool. The immense weight of this water can exceed the roof’s structural load capacity, creating a serious safety hazard while overwhelming the entire waterproofing system.

Flashing and Penetration Failures

Anywhere the flat plane of the roof is interrupted is a potential weak point. These penetrations must be sealed with flashing—a transitional waterproofing material.

- Roof Penetrations: Vents, pipes, skylights, HVAC units, and satellite dish mounts all require careful flashing. The seal between the flashing and the penetration, and the flashing and the roof membrane, can fail over time due to sealant deterioration or differential movement between materials (e.g., a metal pipe expanding at a different rate than the concrete roof).

- Parapet Walls and Terminations: The junction where the horizontal roof membrane turns up a vertical parapet wall is a high-movement, high-risk area. If the flashing (known as a cant strip or termination bar) is improperly installed or fails, it creates a major entry point for wind-driven rain.

Understanding these root causes is why a professional diagnosis is critical. A roofer won’t just patch the leak; they will identify and correct the underlying condition—be it poor drainage or a failing membrane—to ensure a durable, long-term solution.

The Professional Roof Slab Leak Repair Process Explained

When it comes to roof slab leak repair, a professional approach is a systematic, multi-stage process designed to deliver a permanent solution, not a temporary patch. At Smithrock Roofing, we understand that cutting corners on preparation or material selection inevitably leads to recurring leaks and greater expense down the road. Here’s a detailed breakdown of how our experts diagnose, prepare, and repair a leaking concrete roof slab.

Step 1: Thorough Inspection and Aggressive Surface Preparation

The success of any waterproofing system is 90% preparation. The repair is only as good as the surface it’s bonded to.

- Detailed Assessment: The process begins with a comprehensive inspection far beyond the visible leak area. Using tools like thermal imaging cameras and non-invasive moisture meters, we map the entire moisture footprint within the slab. We visually inspect for all cracks, signs of spalling, failing sealants, and issues at penetrations and parapet walls. In some cases, a core sample may be taken to analyze the composition and condition of the existing slab and any underlying membranes.

- Surface Cleaning and Decontamination: The entire roof surface must be impeccably clean. We use high-powered pressure washers (3000-4000 PSI) to remove all dirt, algae, moss, efflorescence, and failing paint or coatings. Degreasing agents may be used to remove oils or other contaminants.

- Creating a Sound Substrate: A clean surface isn’t enough; it must be structurally sound. We use hammers and chisels to sound out and remove any loose, spalled, or crumbling concrete. The goal is to reach a solid, stable substrate. For widespread surface degradation or to profile the concrete for a new coating, mechanical preparation methods like diamond grinding, shot blasting, or scarifying may be employed. This creates a textured surface profile (CSP) that allows the new waterproofing materials to achieve a tenacious mechanical bond.

- Ensuring a Dry Surface: Most waterproofing systems require the concrete to be completely dry for proper adhesion. We use moisture meters to confirm the slab’s moisture content is within the manufacturer’s specifications before proceeding. Forcing an application on damp concrete will lead to blistering and failure.

Step 2: Meticulous Crack and Damage Repair

With a clean, sound, and dry surface, we address the specific points of failure.

- Crack Repair – Routing and Sealing: For non-structural or dormant cracks, we use an angle grinder to route out the crack into a clean, V-shaped channel at least 1/4 inch wide. This removes any weak material and creates a reservoir for a high-quality, flexible polyurethane or polysulfide sealant. The sealant is then tooled to ensure it fills the reservoir and bonds to the sides, allowing it to flex with the concrete’s movement without tearing.

- Epoxy Injection for Structural Cracks: For deep, structural cracks that compromise the slab’s integrity, we use low-viscosity, high-strength epoxy injection. Small ports are installed along the crack, which is then sealed at the surface. The epoxy resin is injected under pressure into the lowest port until it flows out of the next one up, ensuring the crack is filled from the bottom to the top, effectively \”welding\” the concrete back together.

- Polyurethane Grout Injection for Active Leaks: For cracks that are actively leaking water, we inject a hydrophilic or hydrophobic polyurethane grout. Hydrophilic grouts aggressively seek out water and expand to form a flexible, closed-cell foam gel, creating a tough, resilient seal. Hydrophobic grouts react with water to form a rigid foam that repels water and can be used to fill large voids.

- Patching Voids and Spalls: Larger voids and spalled areas are repaired with a high-strength, polymer-modified repair mortar. The area is primed, and the mortar is applied in layers and troweled to a smooth, level finish that integrates seamlessly with the surrounding slab.

Step 3: Applying a New, Robust Waterproofing System

After all repairs are complete and cured, we apply a new waterproofing system to provide comprehensive, long-term protection. The choice of system is critical and depends on the roof’s condition, use, and budget.

- Cementitious Waterproofing: Ideal for slabs with high moisture drive, these systems consist of a blend of Portland cement, fine aggregates, and proprietary acrylic polymers. Applied as a thick slurry in two coats, they cure to form an incredibly durable, hard-wearing barrier that becomes an integral part of the concrete. Crystalline cementitious systems contain chemicals that penetrate the concrete’s pores and react with moisture to form insoluble crystals, permanently blocking water pathways from within.

- Liquid-Applied Membranes (Elastomeric Coatings): This is a popular and highly effective method. High-performance coatings like silicone, polyurethane, or acrylic are applied in multiple layers with rollers or sprayers. The process typically involves a specialized primer, a base coat (often reinforced with a polyester fabric over cracks and joints), and a UV-stable top coat. The result is a seamless, flexible, and fully adhered membrane that can bridge minor cracks and withstand thermal movement. Reflective white or light-colored options can also significantly reduce roof temperature and lower energy costs.

- Sheet-Based Membranes: For the ultimate in toughness and puncture resistance, sheet membranes are the gold standard. Torch-on membranes (modified bitumen) involve applying a layer of asphalt-based sheets using a large propane torch to melt the underside and fuse it to the primed slab and to overlapping layers. Self-adhered membranes (like EPDM rubber or peel-and-stick modified bitumen) are rolled onto the primed substrate and offer a safer, flame-free application while still providing a durable, waterproof layer.

Throughout this process, we adhere strictly to manufacturer guidelines for application thickness, environmental conditions (temperature and humidity), and proper curing times. Rushing these steps is a recipe for failure. For more details on our approach, visit our Roof Repair Services page. We believe in doing the job right, once.

DIY vs. Hiring a Professional: Making the Right Choice

When you discover a leak in your concrete roof, the immediate question is whether to tackle the repair yourself or to call in a professional. The allure of saving money with a DIY approach is strong, but roof slab leak repair is a high-stakes project where a mistake can lead to catastrophic consequences. This is not a simple handyman task; it’s a specialized trade that protects the structural integrity of your entire home.

Let’s break down a realistic comparison of the two approaches:

| Factor | DIY Approach | Professional Approach |

|---|

| Cost | Lower upfront material costs for consumer-grade products. High risk of much larger costs later due to failed repairs, trapped moisture, and exacerbated structural damage. | Higher initial investment for a comprehensive solution. Includes professional diagnosis, commercial-grade materials, labor, and warranty, providing long-term value and preventing costlier future repairs. |

| Time | Can consume multiple weekends or even weeks. Involves a steep learning curve, research, material sourcing, and the high probability of trial-and-error. | Efficient and predictable timeline. An experienced crew can often complete a full repair and waterproofing project in 2-5 days, minimizing disruption and exposure to the elements. |

| Tools & Equipment | Requires purchasing or renting specialized equipment: pressure washer, angle grinder, injection guns, moisture meter. Lacks access to professional diagnostic tools like thermal cameras. | Professionals arrive with a full arsenal of commercial-grade equipment, including thermal imagers, electronic leak detectors, mechanical surface grinders, and all necessary safety gear. |

| Safety | Extremely high risk. Involves working at heights without proper training or fall protection. Risk of chemical exposure from resins and solvents. Liability for any accidents rests solely on the homeowner. | Licensed and insured professionals with extensive safety training (e.g., OSHA certification) and proper personal protective equipment (PPE), including harnesses and fall arrest systems. Protects the homeowner from all liability. |

| Warranty | Absolutely no warranty. If the patch fails in the next rainstorm, you are back to square one, having wasted time and money. | Comprehensive warranties are standard. This includes a manufacturer’s warranty on materials (often 10-20 years) plus a contractor’s workmanship guarantee (typically 1-10 years), ensuring peace of mind. |

| Results | Typically a superficial, temporary patch. Fails to address the root cause (e.g., poor drainage, structural movement). High likelihood of the leak returning, often in a different spot. | A permanent, systematic solution. Addresses the underlying cause of the leak and installs a complete, durable waterproofing system designed for long-term performance. |

When a DIY Approach Might Seem Possible (And Why It’s Still Risky)

A DIY fix should only ever be considered an emergency, temporary stopgap for a very minor, easily accessible, non-structural hairline crack. Applying a tube of polyurethane sealant from a hardware store might prevent water intrusion for a short period. However, the risks are substantial. If you apply a sealant over a damp crack, you can trap moisture inside the concrete, accelerating rebar corrosion. If you use the wrong material, it can fail quickly or be incompatible with a future professional system, making the eventual permanent repair more difficult and expensive. Furthermore, any work on a roof, no matter how brief, carries a significant risk of falls. Without proper safety equipment and training, the danger is simply not worth the minimal potential savings.

Why Professional Roof Slab Leak Repair is a Necessary Investment

Roof slab leak repair is a complex science. A professional brings an understanding of building physics, material science, and structural engineering that is impossible to gain from online videos.

- Accurate Diagnosis: The most valuable service a professional provides is the correct diagnosis. They can differentiate between a simple crack and one that indicates a serious structural problem. They use specialized equipment like thermal imaging cameras to see the full extent of the problem, ensuring the repair covers all affected areas, not just the one spot where water is dripping.

- Material and System Knowledge: A professional knows which of the dozens of available systems—epoxy injections, crystalline slurries, liquid membranes, torch-on bitumen—is the right solution for your specific situation. Using the wrong product will guarantee failure.

- Safety, Licensing, and Insurance: Professional roofing contractors are licensed, bonded, and insured. This protects you completely from any liability in the unfortunate event of an on-site accident. Their crews are trained to work safely at heights, managing risks that are unacceptable for an untrained homeowner.

- Meaningful Warranties: A professional repair comes with a guarantee. This is your ultimate assurance of quality. It’s crucial to understand the two parts: the manufacturer’s material warranty, which covers defects in the product itself, and the contractor’s workmanship warranty, which covers leaks resulting from installation errors. A reputable contractor like Smithrock Roofing will stand behind their work, giving you the peace of mind that the job was done right the first time.

While a professional repair has a higher upfront cost, it is an investment in your property’s longevity and safety. It is almost always less expensive than the cumulative cost of a failed DIY attempt followed by a professional intervention to fix both the original leak and the faulty repair. If you have an active leak, don’t wait for the damage to worsen. Contact us for Emergency Roofer services or learn more about budgeting for a proper fix on our Roof Repair Cost page.